A group of investigators from the Harvard University School of Engineering and Applied Sciences (SEAS) announces the development of a new method for creating 3D patterns and dots on the surface of various materials. This technique could be used for creating advanced metamaterials.

This accomplishment will undoubtedly come in handy when scientists try to build new classes of materials based on extremely specialized specifications. Metamaterials are generally used to create advanced sensors and optical systems, create invisibility cloaks, and other such applications.

What the SEAS team did was essentially find a way of using extremely short and powerful infrared laser pulses to create patterns of silver dots within the very structure of a target material. These patterns constitute the foundation of several classes of metamaterials.

These entirely-artificial structures are developed with the express purpose of influencing light in ways that are impossible with naturally-occurring substances or materials. They are developed from scratch, according to precise specifications, and the process is extremely resource-intensive.

Investigators with the research team published details of their new nanoscale metal lithography method in the latest issue of the esteemed scientific journal Applied Physics Letters. They add that the approach has a sufficiently high level of resolution to enable large-scale practical applications.

“If you want a bulk metamaterial for visible and infrared light, you need to embed particles of silver or gold inside a dielectric, and you need to do it in 3D, with high resolution,” explains SEAS graduate student and lead study author, Kevin Vora.

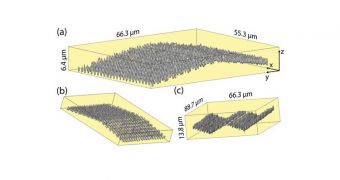

“This work demonstrates that we can create silver dots that are disconnected in x, y, and z. There’s no other technique that feasibly allows you to do that. Being able to make patterns of nanostructures in 3D is a very big step towards the goal of making bulk metamaterials,” he goes on to say.

Vora says that researchers at Harvard, led by the Balkanski Professor of Physics and Applied Physics, Eric Mazur, are using a femtosecond infrared laser in their approach. Such a device is capable of generating pulses of light lasting for only one millionth of one billionth of a second.

In order to create the substrate for the new metamaterials, the team creates a solution containing silver nitrate, water, and a polymer called PVP, which is then baked on a glass slide. When subjected to laser pulses, the silver ions are photoreduced, and form nanocrystals on top of the polymer matrix.

“Normally, when people use femtosecond lasers in fabrication, they’re creating a wood pile structure: something stacked on something else, being supported by something else. If you want to make an array of silver dots, however, they can’t float in space,” Mazur concludes.

14 DAY TRIAL //

14 DAY TRIAL //