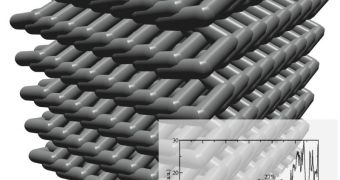

A team of researchers have created a structure made of germanium, a material with a higher refractive index than silicon that looks like an inverse woodpile structure, with excellent optical properties due to its extremely large photonic band gap.

What is an inverse woodpile structure? Exactly what the name suggests, only it's not made of wood. Just like firewood stacked together in a fire, the pieces are placed close to each other and all the gaps are packed with ice. Then, the wood is carefully removed and the remaining shape is the latest photonic structure.

Paul Braun, a University Scholar and a professor of materials science and engineering at the University of Illinois, together with a team of researchers, have published a paper where they present the new inverse woodpile structure.

"Until now, all woodpile structures have been composed of solid or hollow rods in an air matrix," said Braun. "Our structure is composed of a germanium matrix containing a periodic array of tubular holes, made possible by a unique and flexible fabrication technique."

Their structure, apart from being made of germanium, which naturally possesses a higher refractive index than silicon, also has one of the widest photonic band gaps ever reported.

"A wider band gap means there is a broader spectral range where you can control the flow of light," said Braun, who also is affiliated with the university's Beckman Institute, Frederick Seitz Materials Research Laboratory, and Micro and Nanotechnology Laboratory. "In many applications, from low-threshold lasers to highly efficient solar cells, photonic crystals with wide band gaps may be required."

In order to produce the structure, they created a polymer template by using a robotic deposition process called direct-write assembly. This involves a polymeric ink, concentrated and then dispersed as a filament to form the woodpile rods, from a nozzle approximately 1 micron in diameter (a micron is 1 millionth of a meter, approximately 50 times smaller than the diameter of a human hair).

Many consecutive layers are deposited one atop another to create the three-dimensional structure, which was then coated with a layer of aluminum oxide and silicon dioxide, to enlarge the rods and increase the contact area. The remaining space was filled with germanium.

By burning away the polymer template and dissolving the oxide coating by acid, a tiny block of germanium with an inner network of interconnected tubes and channels is the resulting structure.

The new structure could have many practical applications, like low-cost microelectromechanical systems, microfluidic networks for heat dissipation and biological devices.

14 DAY TRIAL //

14 DAY TRIAL //