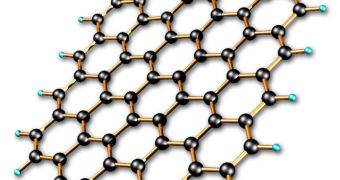

A group of investigators from the Rice University announces the development of a new method for producing bulk amounts graphene oxide (GO). The approach can also be used to break up large quantities of the compound, which means that the team essentially developed a new means of ensuring a steady supply of the stuff. Graphene is a carbon compound featuring a honeycomb-like structure, and unique physical and chemical properties. It was discovered in 2005 by researchers at the University of Manchester, in the United Kingdom.

Graphene is only one atom thick, and its hexagonal structure is the source of its captivating properties. These are what make it a huge promise for the electronics industry. There is a high chance that the microchips of tomorrow will not be based on silicon, like they are today, but on this new material. But in order for that to become a reality, more research is needed into the behavior of graphene, as well as into methods of producing it inexpensively. A paper detailing the newly-proposed method was released from the lab of Rice chemist James Tour, the leader of the investigation. The work was published online this week in the esteemed scientific journal ACS Nano.

In a second paper, appearing in the same journal, Tour and colleague Andreas Luttge demonstrate a new method of breaking down GO, using bacteria. Luttge is a Rice professor of Earth science and chemistry. The team says that the microorganism they developed can pass through graphene, breaking it up, and producing only graphite in return. If needed, graphite can be used to obtain graphene. “These are the pillars that make graphene oxide production practical,” explains Tour. He is a professor of mechanical engineering, materials science and computer sciences at the university, as well as the Rice T.T. and W.F. Chao Chair in Chemistry.

“Many companies have started to make graphene and graphene oxide, and I think they're going to be very hard pressed to come up with a cheaper procedure that's this efficient and as safe and environmentally friendly,” the expert argues. He explains that the utility of graphene lies within its versatility. Even though it is an insulator in its natural state, graphene can be turned into a conductor or semiconductor via chemical reduction. Possible applications outside of the electronics industry include the creation of hydrogen storage devices, and the development of advanced, drug-carrying nanoparticles.

14 DAY TRIAL //

14 DAY TRIAL //