Additive manufacturing technology, otherwise known as 3D printing, seems to spark some new breakthrough in the field of medicine every other day. Researchers from Louisiana Tech University have just revealed the latest advancement.

It appears that researchers from the University, both faculty and doctoral students, were able to create their own custom 3D printer filament.

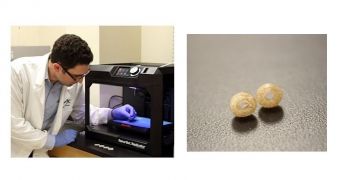

This would not be such a big deal, if not for the possible uses of the filament. You see, the filament can be used to make implants on a normal MakerBot Replicator 3D printer.

Not just any implants either, but ones that are loaded with drugs, like antibiotics or chemotherapeutics. The idea is to implant the, well, implants inside the body and allow the organism to absorb the drugs inside, and even decompose the implant itself over time.

It's a new potential treatment method for many ailments and infections, one that could pose very few risks, especially in the long term.

To make the filament, the faculty and doctoral students within the school’s biomedical engineering and nanosystems engineering programs cobbled together a filament extruder capable of producing a filament made of biocompatible material.

The filament can include the medical compounds we mentioned, but it can easily be processed by a MakerBot Replicator 3D printer.

Jeffery Weisman, a doctoral student in Louisiana Tech’s biomedical engineering program, explained that the filament contains nanoparticles and other additives.

With the help of nanosystems engineering doctoral candidate Connor Nicholson, he and their team were able to explain to Phoenix, Arizona based Extrusionbot, LLC what materials to supply them with.

In the end, they were successful in 3D printing a drug emitting implant that can break down in the human body over time, gradually releasing the medication to a particular area. Definitely beats having to ingest a pill or get an injection that could waste most of their healing potential by dispersing through the whole body.

There are other forms of drug implants of course, but they're usually in the shape of beads that are molded out of hand-mixed bone cements, which have the unfortunate drawback of containing carcinogens. Also, they don't break down, meaning you'll have to go through a second surgery to get them out.

The 3D printed drug implants look really like small yellow balls, as the images show. We can definitely see them being used as standard part of certain treatments in half a decade or so. Just a few trial runs to go through first.

14 DAY TRIAL //

14 DAY TRIAL //