Even though multitouch has been introduced rather recently, capacitive touch technologies can only handle, at most, two simultaneous touch inputs. Stunningly, however, Ken Perlin, Ilya Rosenberg and a team from the New York University’s Media Research Lab have come up with a new touch technology that will not only handle an unlimited number of simultaneous touch inputs, but will even be capable of recognizing pressure differences while costing very little. The technology is known as I.F.S.R., which is the short version of Interpolating Force-Sensitive Resistance technology.

The team has already founded its own company, Touchco, and its technology promises to give complex and extremely intuitive multitouch capabilities to all kinds of products, from electronics to new types of musical instruments.

The technology is already in advanced stages and Mr. Perlin estimates that products based on it should already appear during 2010. The I.F.S.R. was already demonstrated to be capable of relaying different commands to the machine, depending on the pressure applied. For instance, light brushes against the sheet moved the cursor, while increased pressures enabled the selection and manipulation of objects. This feat is capable thanks to the use of Force Sensitive Resistors, detailed on the company's website.

“Force Sensitive Resistors are materials that become more conductive as force is applied. FSR ink is bumpy at a microscopic level so that when two ink-coated surfaces are pushed together, the surface area in contact increases. When this happens, electricity flows from one layer to another. FSR sensors operate by sandwiching layers of FSR ink between sheets of plastic printed with conductive wires. When pressure is applied to a point on an FSR sensor, current flows from powered wires in one layer, through the FSR ink, to wires in the other sheet. Measuring how much electric current flows through the system tells you how much force is being applied.”

Normally, using FSR arranged in a grid is impractical, economically wise, since such an arrangement requires hundreds of thousands of sensors. Touchco developed, however, “a scanning technique and positional interpolation to measure touches at a resolution much finer than that of the actual wiring.”

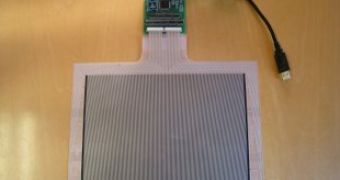

The I.F.S.R. Sheets are 0.01 inches thick (0.25 mm) and may come in multiple form factors, including a 21" x 12" large desktop sensor , a 11" x 8.5" medium desktop sensor, a 3" x 2.5" mobile device sensor, a 14" diameter large drum sensor and an 8" diameter small drum sensor. Their speeds range between 60 Hz and 500 Hz and their resolution is of 100 dpi (254 µm). The maximum resolution can even be increased through finer wire spacing.

For those interested in the full technical details of the technology, the official website has a complete description of both the way the I.F.S.R. works and the aforementioned form factors. End-users, however, will likely be more interested in hearing how genuine drawing will be possible. With the help of a supporting piece of software, the technology will be able to make the difference between pencil thickness and even correctly differentiate between the palm, the pencil and the eraser. This feature is owed to the technology's ability to detect the softness, shape and pressure of each touch input, regardless of how many simultaneous inputs there are.

E-readers, netbooks, notebooks and other consumer electronics, as well as musical instruments based on Touchco's new technology will supposedly emerge next year. This probability is quite strongly supported by the fact that the sheets' manufacturing cost is extremely low, with the price for each square foot expected to reach as low as $10.

14 DAY TRIAL //

14 DAY TRIAL //