Most metal 3D printers seen so far, not that there were so many of them, were the sort of thing that you could have fit inside your garage or workshop with some inventiveness on your side. This cannot be said about the newest one from Sciaky, however.

The company, a subsidiary of Philips Service Industries (PSI), has put together a 3D printer meant to become part of factory manufacturing lines, although perhaps it would be more accurate to say it is meant to replace conventional production lines instead.

Normal manufacturing facilities involve processes made of several steps, depending on what sort of object or part of an object you are making (airplane parts, car chassis components, etc.).

3D printers can build those objects in a single go and over a much shorter period of time, since there are no metal melting, shaping, hammering and cooling stages to alternate and wait between.

Sciaky has been making Electronic Beam Additive Manufacturing (EBAM for short) machines since 2009. Now, a 3D printer ready to be installed in factories has been completed.

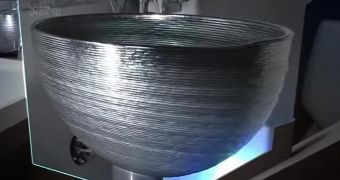

The 3D printer uses a moving electron beam to deposit metal, layer by layer, according to a 3D model viewed in a CAD program (computer-aided design). The list of supported metals include tantalum, stainless steel, cobalt alloys, nickel alloys, copper nickel alloys, inconel and titanium.

Lockheed Martin, DARPA, Boeing and other companies that produce large-scale prototype and production parts are bound to be interested in the acquisition of these printers.

To be fair, many other corporations will probably look them over, but they aren't likely to afford many of them. We don't know the price yet, but it should be in the range of millions, or tens of millions of dollars / euro.

Why? The build size, for one. You can use the Sciaky EBAM machines to make objects as large as 19 x 4 x 4 feet / 5.79 x 1.21 x 1.21 meters. Secondly, the corporation has worked hard to make sure very little metal is wasted (if any), drastically reducing material costs.

Machining/manufacturing time is significantly cut down as well, by 80% or so, and the greatly shortened lead times further boost the efficiency of all processes and, with it, the profitability of the overarching business.

The video below shows an example of what Sciaky's EBAM 3D printers can accomplish. Don't mind the rough looks, since post-processing and polishing won't be dropped for a long time still, no matter how high the resolution of the 3D printing technology becomes.

14 DAY TRIAL //

14 DAY TRIAL //