A water jet cutter is a tool able to slice into various solid materials with the help of a high speed jet containing a mixture of water and an abrasive material. Basically, water jet cutters rely on the same process that shaped most of the surface of the planet over the course of the past several billion years, water erosion, only that the process is greatly accelerated by the fact that in this case water flows at a much faster rate than in natural conditions.

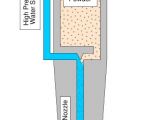

The design of water jet tools is extremely simple and efficient and as you can see in the lower diagram, water is pumped into a nozzle where it is mixed with an abrasive material. Usually, the water pumping part falls in the area of ultra-high pressure pumps, which can deliver pressures between 276 MPa and 600 MPa. The abrasive material is made of a mixture of grit and other additives, such as garnet and aluminum oxide, although water jet cutters can be used without the abrasive compound when slicing through soft solids.

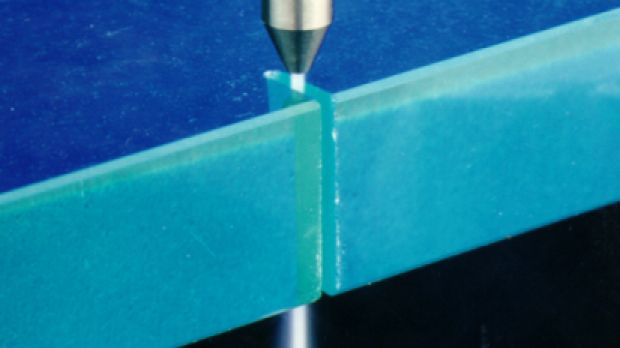

As the water-abrasive material mix exits the nozzle of the device at speeds of up to 1440 kilometers and impacts the surface of the material that needs to be cut, it basically starts stripping tiny bits of matter away from it at high speeds, creating what we observe as a cut in the material.

Advantages

Water jet cutters can virtually slice through any material known to man, except for compounds that shatter when the jet impacts them, such as tempered glass or certain ceramics. Another benefit of using these tools to cut materials is that unlike other devices, water jet tools are not limited by thickness, being able to make incisions as deep as 30 centimeters.

Also, water jet cutters produce relatively little heat during operation, meaning that the material does not suffer from the effects of high temperatures. The width of the cut can be modified easily by simply changing the type of nozzle, to achieve cuts less than 0.0076 millimeters or roughly the diameter of a human hair, meaning that the resulting parts are extremely precise.

14 DAY TRIAL //

14 DAY TRIAL //