Spot welding is a technique generally used to bond metals shaped into sheets no thicker than 3 millimeters. Unlike other welding techniques, spot welding can create precise bonds without generating excessive heating that can affect the properties of the rest of the sheet. This is achieved by delivering a large amount of energy in a short time in order to create controlled and reliable welds.

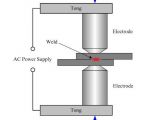

Typical spot welding machines make use of two copper alloy electrodes that are positioned over the area where the bond is to be made. The two sheets of metal that are welded are clamped by the two electrodes while a large electric current is run through them. The technique is also known as resistance spot welding, because the amount of heat delivered on the spot is directly related to the resistance between the electrodes, the amplitude of the current and the duration of the applied electric current.

As a consequence, different metals with various thicknesses require different current amplitudes, types of electrodes and time intervals. For example, if the machine is not properly adjusted it could end up delivering too little or too much energy to the sheets being bonded. In the first case, the amount of energy would simply be insufficient to melt the metals and bond them, whereas if too much energy is inputted the sheets would melt excessively, creating a whole in them rather than a weld.

The energy delivered during the bonding of two sheets must be available instantaneously. In the case of high power demands, the power supply is usually equipped with an energy storage unit, otherwise this constructive element is completely useless.

The electric current required for such applications is produced with the help of a step down transformer (with the electrodes forming the secondary circuit of the device), which lowers the voltage and increases the current (the voltage between the two electrodes rarely exceeds 1.5 volts, except for when there is no galvanic connection between the two, when the voltage increases to 5-10 volts, while the electric current can reach values up to 100,000 amps).

14 DAY TRIAL //

14 DAY TRIAL //