A collaboration of investigators from the Massachusetts Institute of Technology (MIT) and the Politecnico di Torino, in Italy, was recently able to determine how a spider web is so resistant, and capable of enduring high levels of tear and stress.

The resilience of spider web is legendary among scientists, who have observed some of these constructs remain intact even after hurricane-force winds. Investigators have always been curious to learn how the nearly-invisible web is capable of doing that.

While they knew that that very structure of the web filaments themselves made them extremely resilient, about three times tougher than steel at similar scales, they also knew that there must be more to this than met the eye.

For starters, the filaments alone could not explain how a web could survive countless major tears as a whole, without coming apart. One of the things that immediately stood out was that the overall design of the web also played a critical role in determining how individual portions of it would react to stress.

In other words, the web design determined the pattern in which the web will compensate for damage at one location of another. The entire construct is preserved because the spiders design their webs in a manner that localizes both strain and damage.

Details of the new investigation were published in the February 2 issue of the top journal Nature. “Multiple research groups have investigated the complex, hierarchical structure of spider silk and its amazing strength, extensibility and toughness,” scientist Markus Buehler explains.

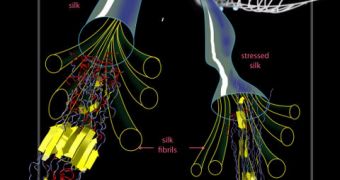

“But, while we understand the peculiar behavior of dragline silk from the 'nanoscale up' – initially stiff, then softening, then stiffening again – we have little insight into how the molecular structure of silk uniquely improves the performance of a web,” he adds.

The expert holds an appointment as an associate professor of civil and environmental engineering at MIT. He explains that the two primary components of any spider web are viscid silk – the wet and sticky type used to capture prey – and dragline silk, which is used for structural support.

One of the aspects that separate the webs from other tough materials, say bones, is the fact that it tends to sacrifice localized areas during damaging events. This ultimately allows the web as a whole to endure.

Evolutionarily, this makes a lot of sense, given the amount of effort that goes into create a web. While some spiders only produce modest webs, others create real masterpieces, which take days to put together.

The new investigation was partially sponsored by the US National Science Foundation (NSF).

14 DAY TRIAL //

14 DAY TRIAL //