A group of physicists from the US Department of Energy's (DOE) Brookhaven National Laboratory (BNL) has recently announced the results of a new investigation, whose goal was to assess the interactions that appear between graphene and metal. The reason why such work is being conducted is because the new material is extremely important for applications in nanotechnology and in the electronics industry.

Graphene was only discovered in 2004 by a team of researchers from the University of Manchester, in the UK. Since then, the single-atom-thick material has been a target of substantial investigations, due to the amazing chemical and physical properties it has. It also features electrical and optical traits that make it superior to a host of other, more established materials. Though methods of producing graphene at the very large scale have yet to be devised, experts estimate that the compound will underlie the computers, digital displays, and electronic sensors of tomorrow, PhysOrg reports.

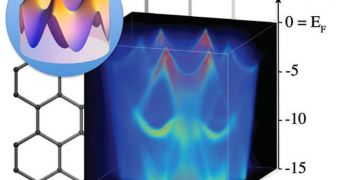

Using a special growth technique, the BNL experts were basically able to extract more thorough information about the electrical and optical properties that graphene has. They developed a way to control the layered growth of the stuff, which is generally produced through the “Scotch tape” method. In this approach, layers of graphene are simply peeled off from larger chunks of graphite. This approach is, however, highly inefficient for producing the stuff.

“Graphene is a material that really has the potential to replace silicon in the electronics industry. It's thin, transparent, strong, and highly conductive – all extremely appealing characteristics for everything from computer chips to touch screens and solar cells,” says BNL Center for Functional Nanomaterials materials scientist Petter Sutter. “One of the unique aspects of this method is that we can control the thickness of the material, growing graphene layer by layer. This has allowed us to see how the structure and electronic properties of the material change as single atomic carbon layers are added to the substrate one at a time,” he adds of the new BNL method to produce graphene on a large scale.

“We found that if a single graphene sheet is grown on a metal like ruthenium, the metal binds very strongly to the carbon atoms and disrupts the characteristic properties normally found in isolated graphene. But those properties re-emerge in subsequent layers grown on the substrate. As a result of this growth process, a two-layer stack acts like an isolated monolayer of graphene and a three-layer stack acts like an isolated bilayer,” he concludes.

14 DAY TRIAL //

14 DAY TRIAL //