Three-dimensional computer chips are industry's new black, and promise unmatched speeds, lower power consumption and smaller chips. No wonder that every company that can afford a research and development facility is tackling the problem their own way. Honda and IBM joined their swords in the quest of the first 3D processor, and it seems they have finally found it.

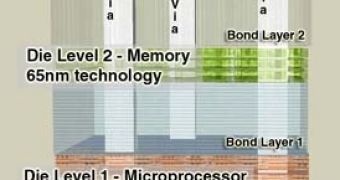

Honda Research managed to achieve this chipset configuration by stacking three distinct chips one on top of another, just like a skyscraper is built. The final unit is comprised of a processing core, a signal converter (analog to digital) and a chunk of memory.

The chips are interconnected vertically, rather than aligned horizontally, on the same PCB which seems to make them more energy-efficient. The explanation is simple: stacking chips on top of each other will allow them to be interconnected with shorter wires than if they had been connected side by side.

Honda researchers noticed that it's the vertical wiring that allows the chip take up 36 percent less power than in a classical, horizontal layout. This is not the only innovation. While horizontal layouts are usually interconnected using tiny bumps of metal put onto both surfaces of each chip, Honda's design require those metal bumps to be attached on the bottom chip only. Instead, these bumps penetrate the entire stack vertically, just like a nail would penetrate different layers of board, for instance.

While IBM has great plans about using this chip design in its future computers and server systems, Honda will implement it in its Asimo intelligent robot for now. Of course, the company will try widening its use as much as possible, since the other semiconductor manufacturers are still stuck with their 3D designs in the testing stage. Honda's chipset isn't yet commercially available, and there will surely be a long way until these 3D designs will power our average desktop systems.

14 DAY TRIAL //

14 DAY TRIAL //