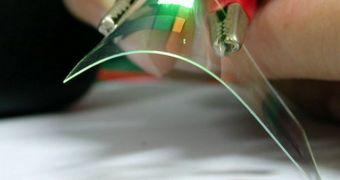

A group of scientists in the United States announces the development of a new type of organic light-emitting diode (OLED), that shine fluorescent blue light with exception energy efficiency.

The new light source was produced at the University of Michigan in Ann Harbor, and its primary application will most likely be in underlying the next generation of display technologies.

These displays will be used in future computers, television sets, cell phones, laptops, tablet computers and smartphones, among other applications. As such, there is great incentive to get them into standardized, industrial-scale production.

OLED are also believed to be the next big thing in billboard and indoor/outdoor lighting applications. The two main types of organic LED available are fluorescent and phosphorescent. The former are now the most commonly used, but also the less energy efficient.

According to the group that conducted the new investigation, that could change soon. Their new fluorescent OLED devices have nearly 10 percent efficiency, as compared to the standard level of 5 percent, in diodes available today.

The light source was created by UM Department of Materials Science and Engineering professor John Kieffer and graduate student Changgua Zhen. The team published its findings in the latest issue of the esteemed journal Advanced Functional Materials.

“Our results clearly indicate that fluorescent material have a bright future for highly efficient and stable OLED for flat-panel display and lighting applications,” Kieffer explains, adding that the material he used for the new diodes was improved using computer simulations.

“With the material, [UM collaborators from Singapore] had some positive results. We took those molecules and started to reconfigure them in a computer model, adding different functional groups in a systematic way,” the professor adds.

“We identified the mechanisms that control the performance of OLED, and by applying the fundamental understanding so obtained we improved the materials characteristics,” Kieffer explains.

“Our research demonstrated the importance of simulation-based predictive design,” he adds. More and more scientists in a variety of fields are beginning to use computer simulations in designing new materials or production processes.

This approach allows them to identify potential problems even before a manufacturing line is constructed to reveal them in practice. The same is apparently true for designing electronic components.

Experts acknowledge funding from the Michigan Memorial Phoenix Energy Institute (MMPEI) and the Institute of Materials Research and Engineering (IMRE).

14 DAY TRIAL //

14 DAY TRIAL //