Researchers at the Massachusetts Institute of Technology (MIT) announce the discovery of a new class of hierarchical structures. The nanoparticles could be used for high-efficiency thermal management in microprocessors, huge powerplant boilers, and many other applications.

The particles were obtained through sintering, a standard process used to create heat sinks for electronic devices. Usually, the process takes place in a vacuum, but a group of MIT students tried it in air, and got a surprising result.

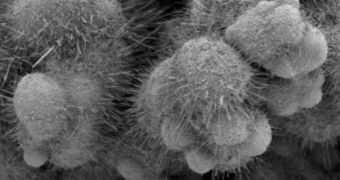

Instead of powdery metals solidified in a certain shape, they got zinc nanoparticles that were covered in fine nanowires. The density of the wires themselves was a direct function of the size of the original zinc particles.

At this time, the MIT group is working on applying the same method on zirconium instead of zinc. If their work is successful, then they might just produce a new heat dispersant material for nuclear reactors.

14 DAY TRIAL //

14 DAY TRIAL //