For the most part, consumer 3D printers use FDM (fused deposition modeling) technology which can create layers of 50 to 500 microns in thickness at a rate of up to a few hundred mm per minute. The faster the less precise.

Things get better in terms of quality as you go from FDM to SLA (stereolithography) and SLS (selective laser sintering), but speed depends on manufacturer and technology application.

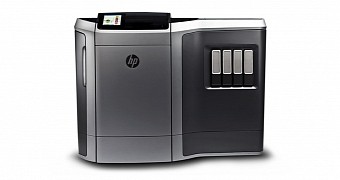

Sniffing an opportune spot where it could strike, HP has finally entered the additive manufacturing sector, and has done so in a world-shaking fashion.

Quite simply, it has introduced a 3D printing technology that is ten times better than current solutions, on both counts.

The HP Multi Jet Fusion technology

After months of putting things off and keeping quiet, HP has finally made its move. The Multi jet Fusion technology uses a multi-chemistry process based on inkjet printing if you can believe it, the type used in paper printing.

A layer of powder is laid down on a platform, after which a fusing agent is introduced at the same time with a detailing agent that produces higher definition around the edges (reduces the fusion on the object boundaries, essentially).

That done, an energy source hits the layer, solidifying and completing it. This process is repeated over and over.

The technology is reputed to go ten times faster than selective laser sintering. To put things into perspective, 1000 gears that would be made in 83 hours of FDM printing and 38 hours through selective laser sintering are made in 3 hours if you use Multi Jet Fusion instead.

All the while, the quality of the objects is guaranteed to be high thanks to the printing process being capable of producing 350 million droplets per second. We can only wonder what it would look like in a macroscale. That's an order of magnitude better precision than on a laser sintering machine.

The implications of the technology

We don't really need to spell them out. We'll just point out that HP intends to form an entire 3D printing ecosystem, which can be taken to mean that a 3D printing store/service chain will be launched soon.

We'll only be able to estimate the impact on consumers once HP releases prices. The company did say that both the printer and the materials used would be more affordable than those available today. But if it's SLS printers they're comparing it against, that's not as encouraging as it sounds.

While there is one affordable SLS printer (sort of, since it still costs thousands), it only prints from nylon and little besides. “Real” SLS printers can create things from metal and cost hundreds of thousands of dollars, even millions. Fortunately, HP is aiming at consumers not factories, so there's room for optimism.

14 DAY TRIAL //

14 DAY TRIAL //