A few years ago, no one would have thought that researchers would end up using the same stuff that makes up pencil mines in order to create the world's next mass-produced, super-fast computer chips. Indeed, it would seem that the conventional way of constructing transistors has reached a dead end, with the increasing demand for ever-smaller ones, crammed as many as possible on very small chips. But miniaturization does not always go well, especially when we're talking about making devices smaller than the distance between two air molecules.

Under these circumstances, forces that have little bearing on the functioning of the circuit when the transistors are macroscopic become increasingly strong as the device itself shrinks. Below a certain point, these forces make it impossible for scientists to construct small transistors that actually work. That's why future progresses in the computer chip manufacturing industry will necessarily have to rely on new construction materials, as the regular silicon chips seem to no longer be able to compete.

Graphene is the next logical choice. It is a carbon compound that can be obtained relatively simply, even though not at the purity needed for creating the chips. Simply take a pencil, and then apply a piece of duct tape on its tip. Gently pull the tape aside, and you'll notice that very small layers of carbon have peeled off the tip, and are now on the duct tape.

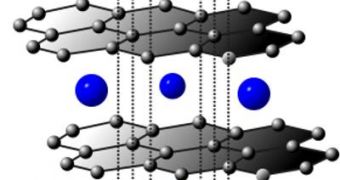

Layers such as those form graphene as well, except that on a microscopic scale. That is to say, the layers you are able to see with the naked eye probably contain at least a few hundred graphene layers, even though they appear to be quasi-transparent.

“We designed the technique to mesh with standard chip-making practices. Graphene has huge potential – it's been dubbed 'the new silicon.' But there hasn't been a good process for high-throughput manufacturing it into chips. The industry has several decades of chip-making technology that we can tap into, if only we could create millions of these graphene structures in precise patterns on predetermined locations, repeatedly. This result is a proof-of-concept that we should be able to do just that,” Ohio State University's Center for Emergent Materials Director Nitin Padture, who is also the Distinguished Professor in Materials Science and Engineering at the College of Engineering, explains in the March 26th issue of the journal Advanced Materials.

“Think of a stack of graphene sheets in graphite as a deck of cards. When you bring it [into] contact with the silicon oxide and pull it away, you can 'split the deck' near the point of contact, leaving some layers of graphene behind. What we found through computer simulations was that the graphene surface interacts so strongly with the silicon oxide surface that the chemical bonds between the graphene layers weaken, and the lower layers split off,” Padture concludes about the new find.

14 DAY TRIAL //

14 DAY TRIAL //