Investigators at Trinity College Dublin, in Ireland, announce the development of a new method for obtaining graphene, a carbon compound that features extremely desirable physical and chemical properties. The material was first synthesized at the University of Manchester back in 2004, and scientists have been trying to find ways of producing it in bulk ever since.

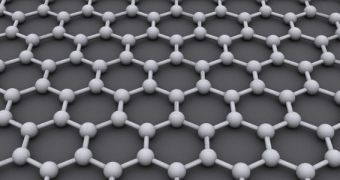

Graphene is a two-dimensional, hexagonal lattice of carbon atoms that features a chicken wire-like structure. This unique atomic patterns make the compound one of the strongest materials ever developed, and allow it to challenge the role silicon plays in modern-day electronic equipment.

However, if graphene is ever to set the stage for a new generation of circuits and electronics, developers will have to have access to bulk amounts of the material. Until now, the compound could only be obtained through complex processes, such as chemical vapor deposition (CVD). A low-cost, high-yield method has thus far eluded scientists.

This is where the new study by TCD researchers comes in. The group found that mixing graphite and stabilizing detergent inside a regular blender can produce large quantities of graphene. The material comes in the shape of flakes that fall off the graphite and are separated from the latter via the process of centrifugation. This type of graphene does not resemble the high-tech variety created through CVD.

Companies such as IBM and Samsung are already involved in producing graphene. Their high-tech approaches grow wafer-scale sheets of single-layer graphene one atom at a time, but the process is time-consuming and extremely complicated. While graphene obtained through the method developed at TCD cannot be used for the same applications as high-tech graphene, it does have its uses.

The blender variety can find great uses in creating conductive coatings and printed electronics, as well as in boosting the mechanical, electrical and thermal properties of composite materials. The latter are used for everything from building cars to spacecraft, and the new additions could extend their range of uses even further, the team explains.

Details of the new approach were published in the April 20 online issue of the top scientific journal Nature Materials. It represents “the fastest way to make large quantities of defect-free graphene,” TCD team leader Jonathan Coleman told IEEE Spectrum in an email. His team also included postdoctoral researcher Keith Paton.

“If you were to try this at home, you could use a household surfactant (dishwashing liquid). However, I'm not sure I'd want to make a smoothie in a blender that has just been filled with graphite,” Coleman concludes.

14 DAY TRIAL //

14 DAY TRIAL //