A team of scientists at the Case Western Reserve University (CWRU) announce the development of a new method for producing graphene in high quantities, and at a low cost. The innovation could open the way for the mass production of high-quality graphene.

The relative unavailability of this material is largely what prevents it from entering mainstream use today. This is due to the fact that standard production processes – such as chemical vapor deposition – are extremely complex, and have low yields.

But collaborators from CWRU and South Korea believe they may have addressed this issue with the new study. Their approach is very basic, since it only involves the use of a simple industrial process, and some dry ice.

The results are nanoscale sheets of high-quality graphene, the team reveals. Thus far, more than 3,000 research papers have covered the world's toughest, most promising synthetic material, and the new process is bound to make that number even larger.

In short, graphene sheets are able to conduct electricity more efficiently than copper. They can also conduct heat better than any other material we know of today. Even though they are tougher than diamonds, these sheets can also stretch. Applications for such a material number in the thousands.

The new production method is detailed in the March 26 online issue of the esteemed journal Proceedings of the National Academy of Sciences (PNAS). The work was led by Jong-Beom Baek.

The expert holds an appointment as a professor and director of the Interdisciplinary School of Green Energy/Advanced Materials & Devices at the Ulsan National Institute of Science and Technology.

“We have developed a low-cost, easier way to mass produce better graphene sheets than the current, widely-used method of acid oxidation, which requires the tedious application of toxic chemicals,” adds the CWRU Kent Hale Smith professor of macromolecular science and engineering, Liming Dai.

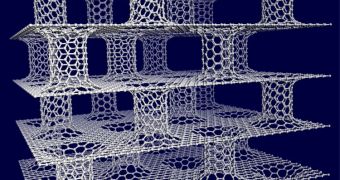

The graphene nanosheets the team can now produce can be used to develop either 2D or 3D structures, to be included in the next generation of batteries, electronics, flexible computer displays and so on.

Graphene has only two dimensions, and features a hexagonal, crystal lattice-like structure. It can be rolled into single-walled carbon nanotubes, which can themselves be used in a wide array of applications.

14 DAY TRIAL //

14 DAY TRIAL //