When you hear "glass", a window pane comes to mind.

Ever tried bending one?

Surely not, since most people are not very fond of glass shards.

And yet, a new type of metallic glass bends in more than acceptable physical limits and "bends" again in commercial products like electric transformers, golfclubs and more.

Ask a scientist and he will tell you that a glass is any material that can be cooled from a liquid to a solid without crystallizing.

Most metals do crystallize as they cool, arranging their atoms into a highly regular spatial pattern called a lattice.

When a viscous material cools very rapidly to below its glass transition temperature, without sufficient time for a regular crystal lattice to form, the silica-based is formed.

The biggest disadvantage of glass is the fact that when in tension, it becomes brittle and easily breaks into smaller or larger fragments.

Unfortunately, the same property that gives normal metallic glasses their strength, also contributes to their propensity to fracture, much like normal glass, because atoms are typically frozen in a random order, like a liquid, an in this case, strain becomes localized in a single plane of atoms that slips past its neighbors, creating a rupture similar to an earthquake fault.

So, metallic glass is not much more resistant than your average window pane, right?

That's why, Wei Hua Wang, a physicist at the Chinese Academy of Science and his colleagues, looked for, and found an answer to the "tensed" problem: they toyed with the composition of long-known metallic glass, made of zirconium, aluminum, copper and nickel, and mixing four or five elements that possess atoms of varying sizes, they came up with a recipe that yielded a mixture of hard, dense regions of the material surrounded by less dense soft zones.

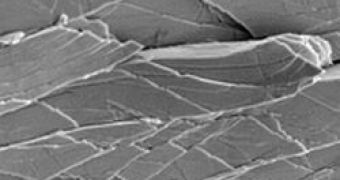

The results are promising, as fractures that began in one area of the material during the bending stopped propagating to the neighboring areas, so the forces that would normally produce a major crack in the material were dissipated into a multitude of small cracks, thus allowing the composite material to bend more than ever before.

This discovery could pave the way for the introduction of new materials in various products, from tougher golfclubs to new structural resistances in buildings.

14 DAY TRIAL //

14 DAY TRIAL //