I knew that it was just a matter of time before 3D printing began to be used by every level of the ever so inaptly named manufacturing industry. But I didn't think it would take so little for the idea to catch on with the ones that make the cutting instruments us men use around our throats every other morning.

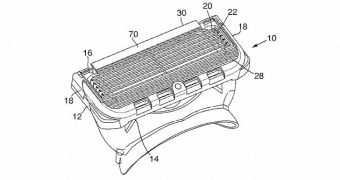

Which is to say, Gillette has decided to start 3D printing its razors. Well, it hasn't actually said it, but it has filed a patent for using 3D printing technology to make a functional razor cartridge.

Right now, 3D printing it only used by a few companies in rapid prototyping, to make mockups and proof-of-concept razor handles they can test out.

Gillette is the first one that wants to 3D print the cartridge though, the part that clips onto the handle.

Previously, no one could even dream of doing this because the precision of 3D printing wasn't high enough to accurately produce the “grill” where the blades are set. That, and there just wasn't an affordable 3D printing technology for it.

Liquid ultra-violet curable photopolymer resin will be used, as well as an ultra-violent laser that will build the cartridges one layer at a time.

It's different from how handle prototypes have been made with FDM printing, where an extruder built the thing drop by drop.

14 DAY TRIAL //

14 DAY TRIAL //