It's called a build volume. A 3D printer has a certain size, ranging from around 2 feet wide / half a meter to 4 meters / 13 feet.

For all the bulk, however, their build volume is quite a bit smaller than their outer size, usually of around half or two thirds of the total. Less if the build chamber has perks like multiple extruders and the occasional upgrade.

For small consumer printers, this can become particularly egregious because you can be limited to small, finger-tall figurines at best. So far, the only saving grace have been designs for modular products, like a chair that assembles out of individually printed pieces.

The Ronin also comes to mind, a 3D printed action figure made of 400 independent parts and featuring 50 points of articulation.

Now, though, your days of having your creative spirit stymied by the limits of the build volume have come to an end. That is the promise of an Indian company called CCTech.

CCTech has introduced a new software program called 3DPrintTech 2.0. Although it is not so much a program as a plugin for Autodesk Inventor 2014, AutoCAD 2014, and SolidWorks 2014.

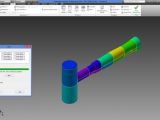

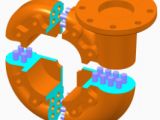

The software divides the designs of larger objects into small, connectable pieces, complete with special 3D printed connectors that the user can customize in several ways. The designer can set the connector radius, the length/taper angle, and even the distance between connectors.

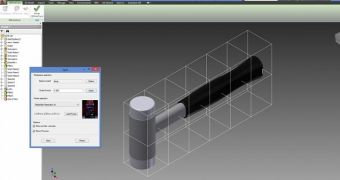

After that, the “3D Packing” feature has to be used. It takes all the objects and automatically packs them up into a single print batch that will make several items at once in your print box. Of course, if you're making something particularly large, you will need more than one batch, but the software is perfectly capable of determining and preparing those second, third, etc. batches in relation to the first.

Benchmarks have shown that the software was able to reduce the 3D printing batches from 10 to 1 (so you could make all those 400 parts of the Ronin in 40 print runs instead of 400). A lot of time and money can be saved this way.

What's left is to see how MakerBot responds to this. The company (now owned by Stratasys) filed a patent to 3D print objects larger than the build volume of a 3D printer back in June, but it has definitely lost its thunder to CCTech now.

14 DAY TRIAL //

14 DAY TRIAL //