We don't really need to bother listing the many science fiction or fantasy writings, films and paintings that depict architectural marvels beyond the ability of man, and indeed beyond the realm of physics.

In a way, it is quite unfortunate that so many things man has envisioned are beyond our ability to reproduce in real life.

Alas, our building materials can't support weight beyond a certain point, especially if you're trying to do anything less basic than stacking. Just building huge domes and chapels is hard enough.

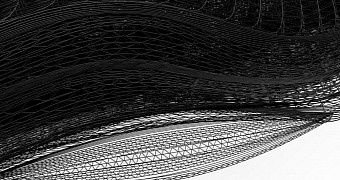

However, that doesn't mean that architects can't give their dreams at least some substance. Sure, we may not be able to make buildings with mesh for walls, but architectural models are a different model.

Usually, it would take a sculptor days to produce a three-dimensional, physical rendering of whatever an architect wants to build. 3D printing has changed that though.

Behold 3D printed architectural models

Bartlett School of Architecture’s RC4 is offering master’s level courses in architecture. The newest such course is for 3D printed architectural models, and eventually, actual buildings.

It is the belief of professors and other experts there that man is ready to start producing more uncanny structures.

The first step is to come up with the plans for odd buildings. The next will be to use 3D printers and 3D printing industrial robots to build the structures to scale.

Ironically enough, it's not just the construction that's hard to do. Digital design can pose problems as well. Fortunately, we've gotten better at it.

The researchers at RC4 say that a very direct computational approach can be used to cut out some steps, like employing mesh, slicing and contouring.

This would allow builders to go straight to the application of material, and the use of 3D models would make it much easier to organize materials in space, and to figure out logistics and structures.

The end goal is to somehow figure out a way to have swarms of 3D printing robots working together on constructing edifices identical to 3D printed models, but much larger in scale. Those edifices would be a statement of uncommon logic and human ingenuity.

Some design examples

Student teams are already submitting their idea for unique projects reliant on vectoral plastic extrusion and 3D printing from more unusual materials (concrete, sandstone, clay, ceramics). The one that stands out most, though, is the SpaceWires from team Filametrics, which you can see in the video below.

14 DAY TRIAL //

14 DAY TRIAL //