We thought that the next time we'd hear about 3D printed buildings would be about a block or skyscraper, but it seems were were aiming too far. Still, a 3D printed estate is a pretty good leap regardless.

That's what a New York City architect and contractor by the name of Adam Kushner has begun to build in the town of Gardiner, along with his partners James Wolff, and Enrico Dini.

Their businesses, KUSHNER Studios and In House Group in New York City have 25 years of experience in construction, having built buildings of up to 80,000 square feet in size (7,432 square meters).

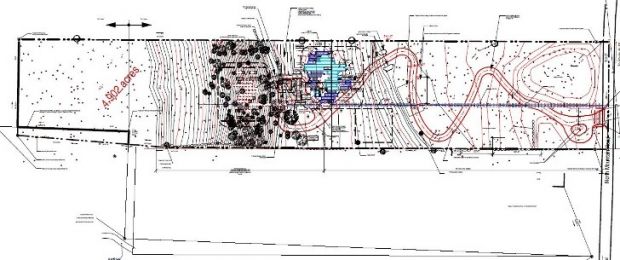

Their new project consists of a 4-bedroom home of 2,400 square feet / 223 square meters, but it's not like they could build a 3D printer as huge as a crane. Besides, that's already better than any other construction 3D printer offered previously.

A modified D-Shape 3D printer will be used, a device invented by Enrico Dini’s which doesn't use concrete. Instead, it employs a magnesium-based building process which combines various materials (usually sand) with a magnesium-based binder to create building blocks not that different from natural stone.

The printer doesn't just make the stones though. It wouldn't really be called a 3D printer estate if you still needed people to carry around the building blocks, or move them with cranes and trucks.

Anyway, in addition to the home the estate will include a 3D printed swimming pool and a pool house. And all it took Kushner to get permission to build the thing was creating his own “method of construction” on the form he had to fill out and send to the New York city department of buildings.

After the “wood, steel and masonry” options, he added “3D printed,” checked it and sent the form, getting the approval quite fast. Even the subsequent inspection of the site went along without a hitch.

So far, the electric grid has been connected to the site of the estate. In a week or so, the electricity should be available, at which point the D-Shape 3D printer will be sent over to start making the swimming pool. It might still take until February 2015 to begin though. Stage 2 will be the pool house and stage 3 will be the actual home.

As construction progresses, Kushner and Dini intend to optimize the 3D printer in any way they can. They believe that the printing of the pool and pool house will allow them to overhaul the contraption until it's a lot more effective and quick. Something that will help when they finally start on the house. Most of the material will consist of crushed rock from the building site itself.

Don't expect this to happen fast, though. While the first house-building 3D printers made a name for themselves thanks to the supposed ability to make a home in 24 hours, that only goes for drab-looking, not-at-all smooth-walled structures.

Kushner intends to stretch the project as long as it takes to iron out the kinks in the building method, so that future endeavors may go smoothly from the start. He thinks it will take 2 years.

14 DAY TRIAL //

14 DAY TRIAL //