Carbon nanotubes (CNT) are now among the most heavily researched materials in the world, due to the promise they hold in furthering research in a large number of fields, from computer sciences to medicine. They could also be used in electronic noses (bomb, drug and hazardous-gas detectors), as well as in devices able to record the passing through of a single electron. But one of the main issues plaguing their production processes is the fact that experts have not yet learned how to produce it of the exact length and overall size required for specific applications. Recently, experts at the Case Western Reserve University (CWRU) developed a method of controlling this production aspect.

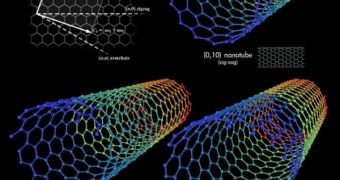

The atomic-level structure of carbon nanotubes, referred to as its chirality, is essential in dictating the final product's size and properties. What the CWRU team managed to accomplish was to devise a way of controlling the chirality using nothing more than various mixes of metals in the CNT production process. In their experiments, the researchers looked at various methods of combining the catalysts, and discovered that the key to controlling the size of the tubes laid within. Their finds are detailed in the September 20th online issue of the respected scientific journal Nature Materials.

“We have established a link between the structure of a catalyst and the chirality of carbon nanotubes. Change the catalyst structure by varying its composition, and you can begin to control the chirality of the nanotubes and their electrical and optical properties,” CWRU School of Engineering Assistant Professor of Chemical Engineering R. Mohan Sankaran, who conducted the research with colleague Wei‐Hung Chiang, PhD, who received his doctorate in chemical engineering this May, explains, ScienceDaily reports.

In their experiments, the two noticed that iron and nickel held the most promises to controlling the chirality of the individual tubes. Furthermore, they discovered that a catalyst of 27 percent nickel and 73 percent iron had the most amazing results, in that most of the produced CNT were semiconducting. At this point, they say, their efforts are focused on measuring the purity of the resulting products, and also on finding a way of incorporating these structures into thin, conducting films, to be used as transistors in next-generation electronics.

14 DAY TRIAL //

14 DAY TRIAL //