Moving the 13 billion tons of ethanol produced yearly in the United States around the country is not an easy task. Transporting it by rail, trucks or barges is not economically feasible, but then again neither is moving it through pipelines, since ethanol-loving bacteria easily degrade the pipes.

Researchers at the US National Institute of Standards and Technology (NIST) found in a new study that microorganisms feeding off the ethanol produce a type of acid that accelerates the degradation of pipes, potentially translating into billions of dollars in damages.

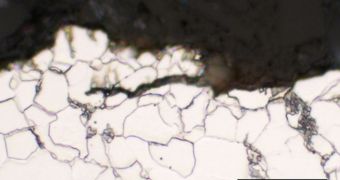

Fatigue cracks develop 25 times more rapidly when ethanol moves through the pipes than when the latter are simply exposed to air. Before the chemical can be transported efficiently to wherever it is needed, this issue must first be addressed, experts said at a conference held this week.

The same damaging effect was found in both fuel-grade ethanol and in ethanol-water solutions. NIST experts arrived to this conclusion after conducting a series of experiments on both chemicals inside a newly-opened biofuels test facility.

The microorganism Acetobacter aceti was found to be most likely to produce the type of acid that causes pipeline corrosion. The chemical attacks steel, causing it to develop so-called fatigue cracking.

“We have shown that ethanol fuel can increase the rate of fatigue crack growth in pipelines. Substantial increases in crack growth rates were caused by the microbes,” explains NIST postdoctoral researcher, Jeffrey Sowards.

“These are important data for pipeline engineers who want to safely and reliably transport ethanol fuel in repurposed oil and gas pipelines,” he goes on to say. Ethanol is primarily obtained from corn, and currently represents one of the most important additives in gasoline.

The reason why it's used for this application is that it boasts a high oxygen content and a higher octane rating than standard gasoline. Fuel-grade ethanol can be used by itself, to power special types of engines. The chemical contains an oxygen atom connected to a hydrogen atom, among others.

This functional group is called hydroxyl, and it is responsible for most of the substance's properties.

The pipes the NIST group used are called X52 and X70. Each of them is made of an alloy of more than 12 metals, and was designed specifically to handle oil or gas transportation. At equivalent pressure and speed levels, ethanol is more damaging than the former, investigators conclude.

14 DAY TRIAL //

14 DAY TRIAL //