It stands to reason that, until robots get human-like appearances, they will never be fully accepted socially. Experts are therefore currently working on ways of making this a reality, but defining what a human trait is proves to be extremely difficult. The best example for this is replicating the human skin. Advancements made recently in studying the organ, such as, for instance, learning how to produce it from stem cells, do not imply a deeper understanding of what makes it human. Measuring its properties and determining which of these properties is key to its abilities is seemingly impossible.

National University of Singapore expert John-John Cabibihana led a team of colleagues in trying to establish just that. They argue that future robots would need to have human-like skin in order to be accepted socially. For example, hand shakes must not feel awkward for people, while the robots' hands must have a natural appearance as much as possible. In addition to use in robots, new skin could be used in artificial, prosthetic devices as well. At this point, visually speaking, prostheses near the aspect of a human arm, but they barely feel like one. Experts are trying to essentially create a coating that would mimic as many of the properties of natural skin as possible, even upon close inspection.

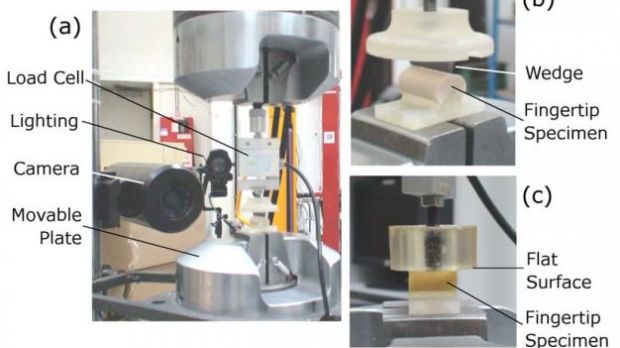

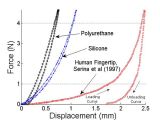

The experts say that creating such an artificial compound is still a long way off. In their experiments, the scientists compared human skin with two of the most popular chemicals used to create substitutes, silicone and polyurethane, and found that they were still a significant distance behind, in terms of abilities. Three main traits were studied, the team reports. The first one was skin compliance, the skin's degree to which it is deformed by a force, the second one was the way its shape conformed to an object it touched, known as conformance, while the third was the difference between the way it deformed and reformed, known as hysteresis.

The investigators mention that particularly difficult to reproduce will be the skin's hysteresis curve, from which silicone and polyurethane were a long way off. The two materials require more force to bend them, but dissipate less energy during this process than natural skin does. The experts' hypothesis is that this trait may result directly from the skin's multi-layered structure. The single-layered approach that artificial skins take seems therefore to be utterly flawed, Technology Review reports.

14 DAY TRIAL //

14 DAY TRIAL //