Multi-material 3D printing has mostly depended on having more than one extruder through which filament has to pass, before being melted and deposited on a growing object.

Unfortunately, there's a very big problem with this technique: the two hotends can touch the printed object haphazardly, with the unused one knocking the print aside while the other tires to add to it, for example.

Thus, it is generally accepted that proper multi-material, multi-nozzle 3D printing can only be achieved if the nozzles are given the ability to change height independently.

The people from England-based company E3D claim to have finally developed a dual-extrusion system that exhibits this all too important capability: the Cyclops.

The new extruder is lightweight and is compatible with all modern firmware, electronics and slicers, in addition to having interchangeable nozzles and a small size of 28 x 30 mm / 1.1 x 1.18 inches.

That means that, in theory, it will work with any bowden and delta printers (the common types of FDM 3D printers).

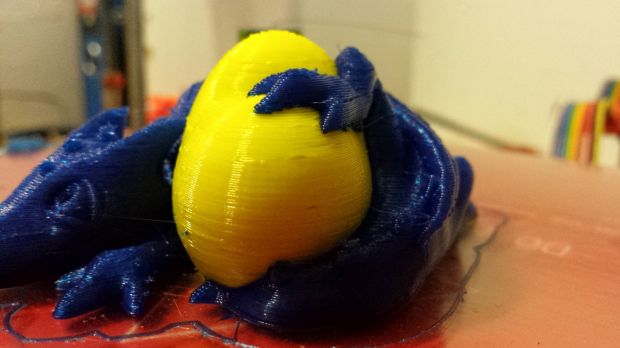

Unfortunately, the Cyclops is still in testing stage, so you won't be seeing it until the E3D beta website goes online. Until then, check out the two attached photos of a sample print made with it.

14 DAY TRIAL //

14 DAY TRIAL //