Patient-specific devices have been hard to get perfectly right up to now, despite how skillful surgeons can be, simply due to the limitations of scans. Now, though, 3D printing technology has enabled almost perfect joint replacements.

They'll never be truly perfect until we can make them out of the exact same substances as the ones naturally developed by the body.

We do have the next best thing though, implants that gradually decompose in the body and allow bone and muscles to grow in place over time.

For some things, though, biodegradability isn't ideal. It wouldn't do to have a femur or joint dissolve without the biological version replacing it.

Knee replacements are just that: replacements that have to stay there until the moment the patient finally passes on to the next great adventure.

The new program from ComforMIS

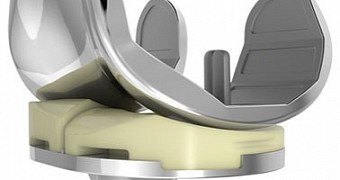

A company from Massachusetts, ConforMIS specializes in medical devices and has begun to create custom knee replacements for individual patients.

Normally, such replacements take a long time to make, and they never truly solve the problem of shattered knees. The full range of motion is not restored, and joint instability can cause pain.

With 3D scans and prints, however, the replacement can have the exact same shape as the original article, eliminating those problems. Since around 700,000 people go through knee replacement surgery each year, this is a very big deal.

The implants emulate the curves and feel of the original knee, and make physical therapy a lot easier to finish too. Patient testimonies said that, without the scar, they could forget they ever had a replacement surgery to begin with.

How the knee implants are made

As has become a standard procedure, a 3D model is developed (using the company's own software) based on CT scans of the patient's joint. The company then makes on-off devices via 3D printing technology.

It's all pretty straightforward really. The hard part was developing the software capable of doing all this, but that's not a trouble anymore. And because of how everything works, the procedure can be done with hips and ankles as well.

What's left is for someone to develop something similar for the softer organs of a human being, but that will take a lot more effort and trial-and-error, not to mention refinements to cell collection and harvesting procedures.

It's one thing to make pin-sized livers for drug testing and another to print a totally new spleen from scratch.

14 DAY TRIAL //

14 DAY TRIAL //