A collaboration of experts in the United States announces the development of a new technique for manufacturing uniform spheres in large quantities, using different materials as a starting point. The study could prove extremely useful for numerous areas of science.

The fabrication method is very versatile, and can be used on multiple materials. One of its most useful traits is that experts can control the design of each individual, macroscale particle individually.

The array of shapes that can be obtained via this approach is very large, and includes more complex ones, such as patterned spheres. Scientists say that the particles they can create will be useful in everything from developing advanced electronics and materials processing to biomedical research.

In addition, the custom-built particles may also be used to deliver drugs inside the human body, for example the chemicals used in chemotherapy today. This could contribute to improving life expectancy for cancer patients substantially.

The work was carried out by experts at the Massachusetts Institute of Technology, in Cambridge, who worked closely with colleagues from the University of Central Florida (UCF). The new manufacturing approach is based on a technique used for creating long, thin fibers from a variety of materials.

Both approaches were created by the same MIT team, experts write in the latest issue of the top scientific journal Nature. The only difference between the two approaches is that the one resulting in the tiny spheres requires one extra step.

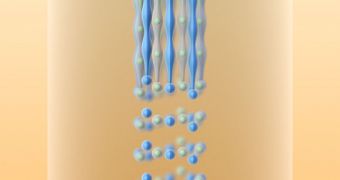

The latter leads to the creation of a line of tiny spheres inside the fibers, which look similar to a pearl necklace. The new study is interesting because it represents a top-to-bottom approach for creating spherical particles, rather than the usual, bottom-up approach that involves growing the particles.

The new production method represents a “major step forward for the scale-up of designed nanoparticles with controlled chemistry and shape,” comments Clemson University researcher John Ballato, who was not a part of the study.

“The ability to harness and control the fleeting fluid instability within a fiber has profound implications for future devices,” adds the director of the MIT Research Laboratory of Electronics, Yoel Fink. He also holds an appointment as a professor of materials science and director at the Institute.

“The work is particularly significant because the approach is scalable, and because of the superior uniformity of the sizes and shapes of the particles produced, compared to what can be achieved using other techniques,” Boston University/Columbia University professor emeritus Malvin Teich concludes.

14 DAY TRIAL //

14 DAY TRIAL //