So far, most attempts at 3D printing electronic circuits and devices have tried to apply this or that additive manufacturing technique. Now, though, there's a new way to go about things. Or perhaps we should say that an existing technique has been discovered.

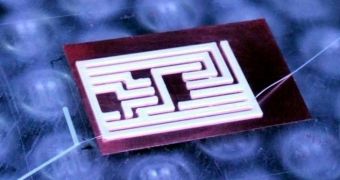

A user on the Instructables website, who goes by the name of Mikey77, was able to adapt his MakerBot Replicator 2 3D Printer in such a way that he succeeded in creating 3D printed circuit boards out of copper.

In truth, what he did can't actually be called 3D printing, since he actually transformed the Replicator 2 into an etching contraption when he did what he did.

First, he started up the 123D Design 3D modeling program, where he drew the PCB board pattern. So far so good – and normal.

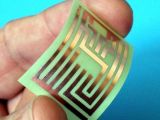

The second order of business was equipping the MakerBot Replicator with Ninjaflex elastomeric rubber filament. Again, so far so good, although compared to ABS, PLA, or nylon filaments, Ninjaflex is already unusual.

Why? Because it sticks to copper clad boards, unlike all the others. This was the key factor in Mikey77's method of making PCBs.

What he did next was spray Loctite, an adhesive available at department stores, over the build platform of the printer.

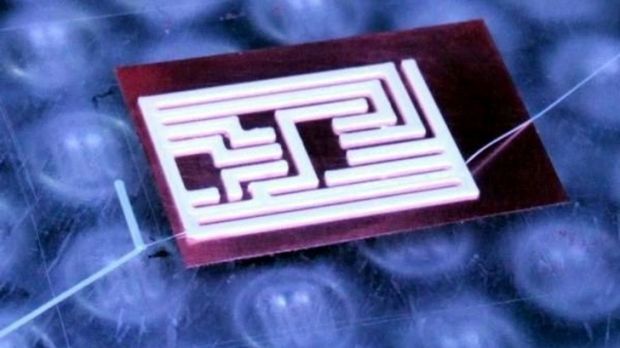

After that and a bit of calibration applied to the MakerBot Replicator 2 printer, the extruder was left at just the right height to print a very fine layer of Ninjaflex on the copper board. A very small margin of error was needed, but he pulled it off.

It's not clear how long it takes to print a PCB like in the attached photos, but it's not everything that needs to be done. After the print is complete, the copper board has to be peeled off the build platform and processed in a Chloride etching solution for approximately 40 minutes at room temperature (the Ferric acid corrodes the copper cladding within Ninjaflex, leaving only the needed conducive copper in place).

Basically, instead of adding circuits to a board by printing the conductive parts, Mikey77 printed a protective layer that would allow the unneeded copper to subsequently be taken off. Kind of reminds me of walking backwards on a tightrope, a fairly common trick in the circus.

Sure, the 3D conductive printing industry isn't big enough to become a circus just yet, but it's only a matter of time. We can already see plenty of manufacturers learning this “trick” of Mikey77 in the relatively near future.

14 DAY TRIAL //

14 DAY TRIAL //