Thermoplastic polyurethane is a material that doesn't easily lend itself to being turned into 3D printable filament, but many 3D printing lovers do their best to use it in that manner regardless, due to its traits.

One such man is called Thomas Palm. What he did was not only create a consumer-level filament from thermoplastic polyurethane, or TPU for short, but also a conductive variant.

He did this by printing carbon into his mixture, his so-called home-made brew if you will. This effectively allows him to 3D print robotic contraptions, or components that can later be assembled into them.

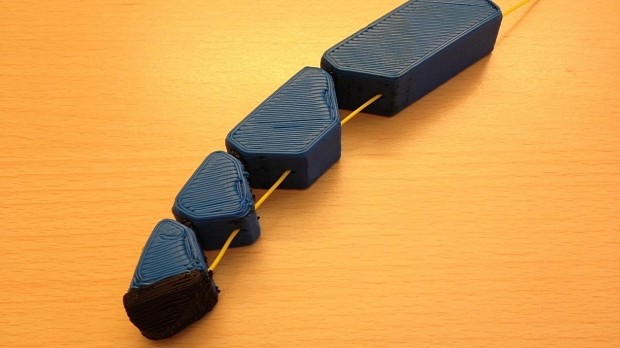

He is already using the TPU to make prosthetics. The gallery holds the first example, one that he actually printed in a single go.

The 3D printed prosthetic finger

It relies more on the flexibility of TPU instead of mechanical joints to provide the finger with the ability to bend.

Palm still had to add the string that would apply the force needed to make the so-called finger to move, but that's about all the post-processing required. Quite remarkable really.

The finger was created with a dual-extruder 3D printer, so it's not something that just anyone will be able to do at home, since dual-extrusion printers aren't common. At least not yet.

Interestingly, the fingertip is force-sensitive. It implies that further tinkering, and perhaps, a nerve interface would be able to provide some tactile feedback.

Not applicable to a test run like this. On the other hand, some of the force feedback can be transmitted through the motion string, and the flexibility of the TPU inner “axis” can combine with it to allow a user to grip things more freely and naturally.

Normally, a robotic prosthesis needs to be very precise when grabbing something, otherwise the hold becomes too weak or too strong.

The pitfall of the TPU 3D printing technique

Palm had to design his own filament extruder to properly use the TPU filaments (both the conductive and non-conductive versions). He expects his TPU and extruder to make it affordable for touch-sensitive fingertips to be installed on robotic prosthetic hands. Also, it will make such prostheses faster and easier to make.

Availability of the filaments and filament-extruder are dependent on whether or not the upcoming crowdfunding campaigns raise enough money. Palm intends to launch both Kickstarter and Indiegogo campaigns in 2015. We'll keep an eye out and report on any new developments.

14 DAY TRIAL //

14 DAY TRIAL //