In what could be likened to a “brute force” approach to characterizing the traits of new photonic metamaterials, researchers are now using combinatorial chemistry to discover materials that could underlie the technology of tomorrow.

A team of engineers in the United Kingdom has recently developed a way of using this approach for characterizing new materials. This could make finding new metamaterials easier than ever.

These particular materials are of interest to optical physics, for example, because some of them have the ability to bend light around them, in very peculiar ways.

This makes them the prime choice for developing invisibility cloaks, layers of covers that could be used to conceal an object from observers in certain wavelengths.

Certain types of invisibility cloaks exist today, but for portions of the electromagnetic spectrum that are invisible to the human eye. Physicists want to extend these capabilities to visible light as well.

Combinatorial chemistry is of tremendous use today, especially for the pharmaceutical industry. Experts oftentimes test thousands of related molecules, in a bid to see which one behaves in the manner they are looking for.

This approach is also used to look for and identify new light-emitting materials, electronic devices and catalysts, Technology Review reports.

British experts at the University of Southampton, who were led by expert Eric Plum, now believe that combinatorial chemistry can also be used to discover new metamaterials.

The goal is to identify unusual electromagnetic properties in these materials, that would make it possible to use them for applications that at this point cannot be completed.

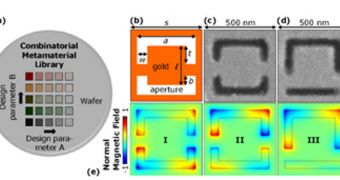

The team explains that the way in which combinatorial chemistry works for metamaterials is relatively simple – create an array of samples in which design parameters fluctuate in a controlled manner.

The team then decides on a type of photons they want to manipulate with the resulting metamaterial, and begins testing the samples until they find an optimized match.

Successive refinements in the process should eventually lead to the desired material. However, one of the drawbacks this approach has is the fact that it's very time consuming.

Additionally, it demands a lot of resources, which means that only large labs and research facilities will be able to use it regularly.

14 DAY TRIAL //

14 DAY TRIAL //