Creating paper cubes out of cross-shaped pieces of paper is something that children learn to do ever since kindergarten. They use the cubes simply to play around, or to store various toys inside. In a similar line of reasoning, a group of researchers from the Johns Hopkins University (JHU), in Baltimore, Maryland, devised a new method of producing precisely patterned carbon nanosurfaces, which can be folded up and modeled into various shapes. The innovation could have deep implications in the fields of medicine and computing, as they would allow for various other nanostructures to be added or binded to them, NewScientist reports.

Over the past few years, experts have been trying to attach organic molecules, vaccines and DNA strands to nanoparticles for various applications in the human body, with various degrees of success. With the new structures, it may become a lot easier to simply store the “cargo” inside the cube, until the exact destination for the ensemble is reached. The active components could then be released, ensuring a considerably higher delivery percentage than with conventional methods. In these techniques, the cargo is simply attached to the surface of the nanoparticles and exposed to outside influence.

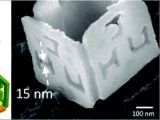

“At the macroscale, everything can easily be patterned in three dimensions. However, nanoparticles with precisely patterned 3D surfaces simply do not exist,” JHU expert David Gracias, the lead researcher of the new experiments, says. A paper detailing the team's achievements can be found online, in the August 14th issue of the scientific journal Nano Letters. The JHU experts have even managed to create nanocubes with their university's initials on the side.

“Since we can build these particles with dissimilar materials [such as nickel and gold], we can construct electronic circuits on the faces to create 'smart' nanoparticles,” Gracias adds. The new boxes are made through an ingenious process. On a silicon substrate, powerful lasers cut the outline of six squares, similar to the cross-shaped paper template used by children. The surfaces of the squares, each some 500 nanometers wide, are covered with a thin layer of nickel. Between each square, grains of tin are placed, to act as hinges.

The process of assembly is, however, a tad more complex. After the desired pattern has been added to a square, either through imprinting with gold, for instance, or by carving it directly into the template, special gases and some heat are applied to the entire structure. The silicon is etched away by the gas, while the tin “hinges” melt and contract, pulling the entire structure into its nanocube shape. According to the Director of the Northwestern University International Institute for Nanotechnology, Chad Mirkin, the innovation could very well represent the nanoscale equivalent of folding proteins inside the body.

14 DAY TRIAL //

14 DAY TRIAL //