California-based SSD company STEC Inc. has just announced the new CellCare technology, on its official website. CellCare is a combination of hardware and software that enables affordable SSDs to last over 40,000 P/E cycles.

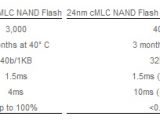

A P/E (program erase) cycle is writing data on every memory cell in your SSD and then erasing it. Usually, newer SSDs only lasted around 3,000 P/E cycles.

This is barely acceptable by our standards, but with each new, smaller manufacturing process, the P/E value of SSDs would have been even lower.

More info on the P/E cycle concept can be found in our Kingston Intros HyperX 3K Solid State Drive news piece and the Kingston HyperX 3K 240GB SATA3 Review.

Most of the SSDs in the market right now are MLC SSDs, but the better performing and more expensive SLC SSDs usually have a significantly increased durability.

The difference in price was still too big for wide adoption of SLC SSDs, and the manufacturing capacity is not enough even for MLC SSDs to satisfy demand.

Therefore, a new technology that would enable long-life, affordable MLC SSDs was needed.

STEC’s CellCare is a combination of hardware and software that simply enables a MLC SSD to reliably function for over 40,000 P/E cycles.

The company claims that, by using CellCare technology, a MLC SSD would last through 10 whole P/E cycles a day for five whole years with data retention rated at three months in a 40 degrees Celsius environment.

This data retention specification of 3 months is perfectly in line with DELL’s official SSD FAQ, but it is way lower than Crucial’s C300 SSD with 34 nm MLC was capable of.

Justin Sykes from Micron has this to say about data retention on a 34 nm C300 SSD:

“Our NAND adheres to the JEDEC specification for data retention, which is 10 years of retention at up to 10% of the maximum specified number or program/erase cycles, and one year after max cycling, at 55°C. (Retention would be significantly better at “room” temp.) This is a baseline number; SSDs built on these retention specs will do equal to or better than this, depending on how sophisticated the controller is and on actual drive temperature.”

Considering that the main issue for enterprise SSDs is not really retaining the data, but enduring multiple P/E cycles a day, this data retention should be a non-issue.

It seems to us that STEC’s data retention specifications are a little more limited, as they require a 40 degrees ambient temperature to achieve three months, while JEDEC certifies data retention using a 50 degrees temperature as the criteria.

Key features of STEC’s new CellCare technology include: Flash parameter tracking per die, which delivers reduced and controlled wear;

Flash management through the lifetime, which delivers reduced wear, controlled performance, improved performance, and lower write/read latency; and

Advanced error correction with digital signal processing to improve data reliability and require a minimum of re-reads.

Looking at the graph of the achieved results we can see that the technology is not quite perfect, as it induces a 250% latency when erasing the memory cell.

We wonder how much this has in common with Fusion-io’s recent achievements regarding SSD endurance.

CellCare will be enabled on all STEC’s SSD products in development.

14 DAY TRIAL //

14 DAY TRIAL //