A team of investigators based at the US Department of Energy (DOE)’s Lawrence Berkeley National Laboratory (Berkeley Lab) announces the development of a new technique that will enable the use of carbon nanotubes in cooling future microprocessors with ease.

Their method is process-friendly, meaning that it can be easily scaled up for mass production. Carbon nanotubes were selected for this investigation because they have remarkable physical and chemical properties. These tubes can be grown directly, or rolled up from 2D sheets of graphene.

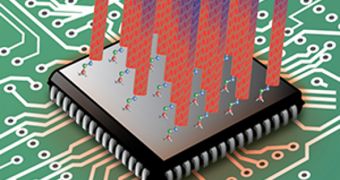

Modern microprocessor chips are capable of extreme performances, but they also generate a lot of heat. Billions of transistors are crammed up within just a few square centimeters, and can easily exceed temperatures beyond the boiling point of water without adequate cooling.

At this point, they can be cooled down by using various approaches, such as a combination of heat-conducting paste and a fan, or water-based cooling circuits. By using carbon nanotubes, the efficiency of future cooling systems may increase several times over what is available today.

The investigation was led by physicist Frank Ogletree, who holds an appointment with the Materials Sciences Division (MSD). The main achievement the team made was figure out a way to use organic molecules as ligands to connect carbon nanotubes to the metallic surfaces of microprocessors, through very resilient covalent bonds.

Heat flow from test microprocessors was improved by 600 percent once the nanotubes were attached, the team reports. Attaching the tubes to the metal surfaces is done via gas vapor or liquid chemistry at low temperature, which means that chip manufacturers can easily adapt their assembly lines.

“We’ve developed covalent bond pathways that work for oxide-forming metals, such as aluminum and silicon, and for more noble metals, such as gold and copper,” adds Ogletree. The expert also holds an appointment as a staff engineer with the Imaging Facility at the Berkeley Lab Molecular Foundry.

“In both cases the mechanical adhesion improved so that surface bonds were strong enough to pull a carbon nanotube array off of its growth substrate and significantly improve the transport of heat across the interface,” he concludes.

Details of the new technique appear in the latest issue of the respected journal Nature Communications.

14 DAY TRIAL //

14 DAY TRIAL //