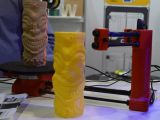

Additive manufacturing is moving faster than almost any other technological field, even solid state storage and supercomputing. After almost three decades of near stagnation, it advanced in three years to the point where it can literally propagate itself.

3D printing technology is about using some method or other, like FDM (fused deposition modeling), SLA (stereolithography) or SLS (selective laser sintering) to build or grow objects drop by drop, layer by layer.

Whether it's superheating plastic to the point of liquefaction, or using a laser to sinter metal powder into a solid, the technology has opened up new ways to fabricate new things.

Meanwhile, 3D scanning has allowed artists and even the common man to create virtual designs that can be replicated via 3D printing by everyone else in the world.

A company by the name of Fuel3D decided to attend the Consumer Electronics Show this year (CES 2015) and show how 3D printing and 3D scanning might combine into an eternal loop.

The 3D printed 3D scanner

3D scanners are normally designed by a person and then put together either by hand or with the assistance of some assembly lines or robots. Same for 3D printers.

However, since the whole point of 3D printing is to eventually make it possible for everything to be 3D printed, no matter how complex, it was inevitable that 3D scanners would be included in the list eventually.

We just didn't expect it to happen so quickly, although maybe we should have, considering that a 3D printer has also been 3D printed.

You might have heard or read about it. We ourselves covered it just days ago, the PCB 3D printer that was 3D printed in Spain.

The new 3D scanner, a handheld point-and-shoot scanner to be specific, is the brainchild of a company called bq. No caps. The scanner uses laser triangulation and a rotating turntable to create virtual models of whatever is placed on the stand.

Availability and pricing

The scanner, called Ciclop, will be put up for order later this year for around $500 / €421 and measures 450 x 330 x 230 mm / 18 x 13 x 9 inches (roughly). It has a scanning speed of 3-4 minutes and 160 to 1600 steps per rotation.

In addition to the 3D printed body, bq used two Logitech C270 HD 1280 x 960 lasers, a 12V 1.5A micro USB Cable for power, and ZUM BT-328 Power Plate controller board, plus a Nema bipolar stepper motor, non-slip surface and threaded rods.

Free Horus software runs the device and outputs files as PLY and STL. Ubuntu, Fedora, Windows 7 and 8 operating systems are supported.

14 DAY TRIAL //

14 DAY TRIAL //