Researchers at the Massachusetts Institute of Technology (MIT), in Cambridge, have recently put together a new method of creating structures at the nanoscale, which they say is cheap enough to be scaled up for practical applications.

One of the reasons why the technique works so well is that it uses both top-down and bottom-up approaches. This allows experts to produce 3D nanostructured materials that feature grooves, shapes and structures measuring just billionths of a millimeter.

These materials will have a wide array of practical applications in the near future, forming the backbone for the next generation of electronic, photonic, phononic and biomedical devices.

Just to set the record straight, this is not the first time that experts produce a method of creating nanostructures. However, all past approaches have proven to be limited in their efficiency. The MIT group managed to surpasses all these obstacles by taking an innovative approach.

The way they achieved their objective was by using a blend of current “top-down” and “bottom-up” approaches. Details of the work appear in the June issue of the esteemed journal Nano Letters.

MIT postdoctoral researcher Chih-Hao Chang, the Singapore research professor of optics and professor of mechanical engineering George Barbastathis, and six graduate students worked together to create this new synthesis method.

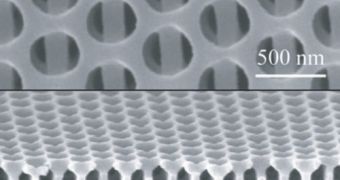

The top-down approach the team used is called phase-shift lithography, and involves a 2D mask shaping the intensity of light shining onto a layer of photoresist material. The areas that are illuminated are modified, so that when the mask is taken off, patterns emerge.

The bottom-up approach involves the use of self-assembling colloidal nanoparticles, which tend to form energetically favorable close-packed arrangements. By combining the two approaches, the team managed to obtain a nanostructure resolution that has never been reached before.

“We do a little bit of both. We took a chemist's method and added in a flavor of engineering,” Chang says of the new hybrid method. The approach “can be implemented as a novel technique to fabricate complex 3-D nanostructures in all fields of nanoscale research,” the team writes in the journal entry.

“It's a very simple way to make 3-D nanostructures, and probably the cheapest way right now. You can use it for many things, [such as creating everything] from holes to higher-density posts, rings, flowery structures, all using the exact same system,” Chang concludes.

14 DAY TRIAL //

14 DAY TRIAL //