The potential uses of 3D printing technology in medicine are many, and organ creation is one of the major end goals. Some things are easier to print than others though, and muscles are among the more complicated ones. That isn't stopping people from researching ways to make it happen though.

Case in point, people from the Factory Automation and Production Systems (FAPS) Institute at Friedrich-Alexander-Universität Erlangen-Nürnberg (FAU) are developing artificial muscles.

By using a 3D printer developed by Optomec, they can create extremely high-resolution prints, and use a variety of conductive materials to create objects.

The technology probably won't lead to the creation of replacement muscle tissue or implantable muscles and tendons, but it might provide prosthetics with a broader range of motion.

FAPS has approached Optomec because they want to create an automated production environment through which electric elastomer actuators may be produced in bulk, or DEAs for short.

If created successfully, DEAs would be used in not only prosthetic devices, but also various game platforms and robots.

Indeed, robots may benefit from the breakthrough quite a bit, or at least the humanoid and animal-inspired ones would, since it would allow for the creation of locomotor systems not too dissimilar from our own.

That would just leave synthetic skin to cover the exposed parts and we'd really have human-looking robots on our hands.

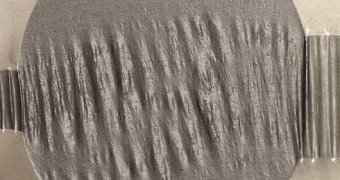

The method used by the Aerosol Jet 3D printer creates homogeneous layers with a thickness below 10 microns, which is a lot better than any FDM printer on the market, which can't go below 50 microns, and usually stick to 100 microns or more.

Dielectric medium and Carbon Nano Tube (CNT) compounded silicon electrodes could be used in conjunction with dielectric medium from those stacked DEAs we mentioned before.

In layman terms, FAPS thinks it can use the Aerosol Jet Print Engine to employ multiple materials at once to make “muscles” in high detail. The technology would also be capable of printing on multiple substrates at the same time.

No clue how long it will take for practical applications to reach the market. It could take months, but it could also take years. We can only wait and see if FAPS gets whatever funds it needs to push the research forward.

No financial concerns were mentioned in any reports, but anything could still happen. At least we can be sure that Optomec will keep the partnership alive for as long as it can, since it only stands to gain from it.

14 DAY TRIAL //

14 DAY TRIAL //