Miniaturized technologies used for space exploration and telecommunications satellites around Earth constitute the central pieces of a new, artificial heart-like device developed by European researchers.

The implant has recently been approved for human trials in France, marking the success of a 15-year collaborative effort between numerous universities and companies in Europe. The prosthetic was developed by Carmat, a spin-off company from EADS Astrium.

The development of such a device has been highly anticipated. Numerous research groups around the world are working on creating a perfect artificial heart, and some designs hold great promise for wide-scale implementation and use. This may also be the case for the Carmat device.

Heart diseases currently affect more than 100 million people around the world. Many patients' conditions become so severe that they need a heart transplant, but the demand far exceeds the supply in this area. This is why artificial hearts are absolutely necessary in modern medicine.

Professor Alain Carpentier, a renowned cardiac surgeon, is the brain behind the new device. He founded Carmat back in 2008 as an off-shoot of Astrium, with support from the French government and a series of investors in France.

Cooperating with Astrium, the space subsidiary of EADS, allowed Carpentier access to a wide array of space-related technologies that are commonly used in space, but not so much here on Earth. What Astrium brought to the table was basically the precision and durability needed to create a lasting medical device.

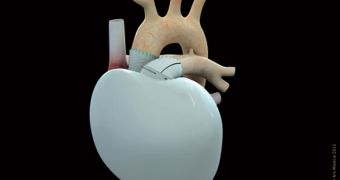

Carpentier says that the artificial heart basically combines the latest advancements in material sciences, biology, electronics and medicine. Half of it is made from organic materials and biological tissues, while the other half is made out of satellite components that have been significantly miniaturized.

“The team had to build a device that could withstand the tough conditions of the body’s circulatory system and pump 35 million times per year for at least five years without fail. They needed the ultimate in reliability, and the answer came from design methodologies, testing strategies and know-how for the electronics on satellites,” experts from the European Space Agency write in a statement.

“Space and the inside of your body have a lot in common. They both present harsh and inaccessible environments. Failure in space is not an option. Nor is on-site maintenance. If a part breaks down, we cannot simply go and fix it. It’s the same inside the body.” explains the leader of Business Development in theFrench Elancourt Equipment team at Astrium, Matthieu Dollon.

14 DAY TRIAL //

14 DAY TRIAL //