Hon Hai Precision (Foxconn) is about to shed 1.6 billion Chinese yuan (around US$161.8 million / €123.8 million) after seeing 5 to 8 million iPhones returned to its production lines over malfunctions and low-quality assembly.

Citing the Taipei-based China Business Journal, PatentlyApple reports that “5 to 8 million iPhones were returned from Apple on March 15 because they were either malfunctioning or didn't meet Apple's standards in terms of appearance.”

It then adds that the newspaper’s source confirmed the 8 million figure, adding that it will cost Foxconn “1 billion (US$161.8 million) to 1.6 billion Chinese yuan to repair the defective handsets.”

The actual iPhone model isn’t mentioned, but it’s reasonable to assume that China’s business newspaper is talking about the latest version of the handset.

Foxconn previously confirmed that Apple’s iPhone 5 is the most difficult to manufacture.

A Hon Hai spokesman named Simon Hsing reportedly denied the figures mentioned in the report, but added that the company would look into management issues and production yield rates.

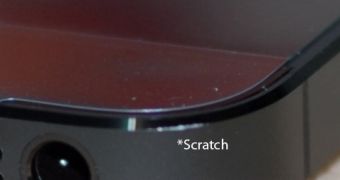

Apple makes the iPhone 5 out of anodized aluminum, and production over at Foxconn has been painstakingly difficult because it’s very easy to scratch the soft metal.

Apple’s quality control checks undoubtedly found dings and scuffs on the easily-damageable iPhone 5 units. After all, some phones actually shipped with their cases damaged.

The news, if confirmed, will most likely take its toll on Apple’s stock price, in a time where the company is already facing difficulties.

The rumor also seems to corroborate some reports saying Apple reduced its orders with suppliers.

If the company is actually forced to return millions of phones to the assembler, the move is most likely affecting sales as well.

The last thing Apple needs right now – ahead of a new iPhone refresh – is for Foxconn to be unable to hold its own.

14 DAY TRIAL //

14 DAY TRIAL //