Fossils can be troublesome things, as it can be dangerous to separate them from the sediment in which they are found. Unfortunately, not doing so can make it impossible to figure what fossil it is, or what animal it belongs to.

3D printing is now offering a means to bypass all risks. Basically, you don't need to separate it from the sediment at all, because the 3D printer will build a replica of it.

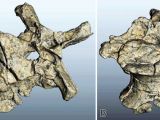

Researchers from Berlin were able to use a computer tomography (CT) scanner and a 3D printer to create a replica of a dinosaur vertebra.

They were able to then trace the fossil to the Halberstadt excavation, a major dig from 1910 to 1927 in a clay pit south of Halberstadt, Germany.

A 320-slice multi-detector system was used to perform the CT scan. In addition to allowing the 3D printer to do its work, the scan also revealed how well the fossil withstood the test of time.

As one should be able to see in the pictures, there are multiple fractures, and the front rim of the vertebral body is more or less destroyed. At least archaeologists can breathe easy knowing it wasn't them that ruined it.

"The most important benefit of this method is that it is non-destructive, and the risk of harming the fossil is minimal," said project head Dr. Ahi Sema Issever, a radiologist at Berlin's Charite University Hospital.

The history of the fossil was lost because of the Second World War. Researchers found the fossil under the bomb rubble of the Museum für Naturkunde. The museum records have always been available, but without a good visual of the fossil, it was impossible to match it to the correct entry.

Now that it has finally been achieved, we can assume that 3D scans and printed mockups will be used for such things again, perhaps even to provide other museums with replicas of fossils for their own collections.

14 DAY TRIAL //

14 DAY TRIAL //