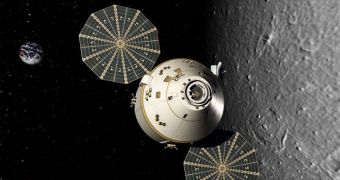

A group of researchers working under the supervision of experts at the NASA Engineering and Safety Center (NESC) have just demonstrated the viability of an all-composite space capsule. During early, full-scale structural tests performed over the past few months, at the American space agency's Langley Research Center, in Hampton, Virginia, it was determined that the new design is equal, and in some respects even better, at delivering astronauts to and from low-Earth orbit (LEO) than conventional, metal-based ones. The class of materials used in the new spacecrafts, which is simply called “crew module,” is the same as the one used for modern race cars, aircrafts and high-end sports equipment.

One of the main things the NESC team was aiming for was developing a space capsule made of materials that could be more structurally efficient. This trait is to be desired for the space vehicles of tomorrow, which will have to endure very long trips, to the Moon and Mars, as well as return journeys. One particular advantage that composite have over conventional metals is that they can be constructed in highly complex shapes and structures, without losing their structural efficiency.

In the Langley tests, the capsule was placed under all sorts of strains over the course of its trials, so as to simulate all possible situations an actual manned spacecraft could find itself in upon atmospheric descent on another planet, an asteroid, or the Moon. The crew capsule was pressurized throughout the tests – as it would be while carrying a crew – and the engineers analyzing its performances even deployed the parachute system, so as to ensure that the strain it placed on the capsule would not depressurize it. No such issues, or problems of any other nature, were found, the team reports.

“Our tests showed that a composite module can ‘achieve the mission’ with damage that is likely to occur but could go undetected. The test article withstood twice the design internal pressures with known damage and then was subjected to cyclic testing to four times the design life with no detrimental damage growth,” explains NESC Composite Crew Module (CCM) project manager Mike Kirsch. “We are very pleased with the entire test series. Throughout testing, there were no anomalies and performance aligned amazingly well with analytical predictions,” the expert adds.

“One of the primary project objectives was to gain hands-on experience for NASA with our contract partners by designing, building and testing a full scale complex structure such as this, then communicate lessons learned to engineers working composites across the agency. There have been many lessons learned, including the challenge of keeping weight down while meeting design requirements for a human-rated spacecraft,” Kirsch concludes, quoted by Space Fellowship.

14 DAY TRIAL //

14 DAY TRIAL //