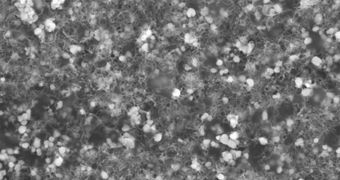

A team of investigators in the United States has successfully developed a new type of advanced coating, which has the ability to destroy methicillin resistant Staphylococcus aureus (MRSA).

This microorganism is one of the most dangerous sources of hospital infections, given that it can survive even in the most harsh environments.

This form of S. aureus is also resistant to various drugs, and it attacks children, seniors and persons with compromised immune systems predominately.

In order to develop a method of destroying it without killing its host, or the surface the bacteria contaminates, researchers at the Rensselaer Polytechnic Institute (RPI) turned to nature for inspiration.

They developed a new coating for walls, surgical equipment and other surfaces, whose design was based on an enzyme that can be readily found in nature.

“We’re building on nature. Here we have a system where the surface contains an enzyme that is safe to handle, doesn’t appear to lead to resistance, doesn’t leach into the environment, and doesn’t clog up with cell debris,” says Jonathan S. Dordick.

“The MRSA bacteria come in contact with the surface, and they’re killed,” adds the expert, who is also the Howard P. Isermann Professor of Chemical and Biological Engineering at the university.

The expert also holds an appointment as the director of the RPI Center for Biotechnology & Interdisciplinary Studies.

He explains that the new coating was capable of killing a full 100 percent of all bacteria in solutions within no more than 20 minutes of making contact. The finding could very well open the way to new solutions aimed at destroying MRSA.

Underlying the new coating is a type of enzyme known as lysostaphin, which is used by non-pathogenic strains of Staph bacteria to steer clear of MRSA infections.

The enzymes were then combined with nanoscale carbon tubes, which allowed for the coating to catch of strength and flexibility.

“If we put an enzyme directly in a coating (such as paint) it will slowly pop out. We wanted to create a stabilizing environment, and the nanotubes allow us to do that,” reveals RPI Department of Chemical and Biological Engineering professor Ravi Kane.

“We spent quite a bit of time demonstrating that the enzyme did not come out of the paint during the antibacterial experiments. Indeed, it was surprising that the enzyme worked as well as it did while remaining embedded near the surface of the paint,” says Dordick.

14 DAY TRIAL //

14 DAY TRIAL //