Using a series of complex techniques, investigators at the University of Bristol, in the United Kingdom, announce that they were able to calculate two critically-important properties of graphene for the first time ever. The material may one day replace silicon in electronics.

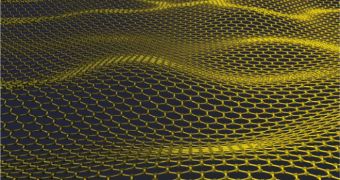

Graphene is a bi-dimensional carbon compound that is made up exclusively of carbon atoms, arranged in a hexagonal pattern. This allows it to display absolutely remarkable physical and chemical properties, and made many believe that it will set the foundation for a new generation of electronics.

However, the thing about this material is that it's relatively new, in the sense that it was only first synthesized in 2004. Even if nearly 4,000 research papers have been written about it thus far, scientists are still painfully aware that they have a lot more to learn about graphene.

This new study is a step in the right direction, the UB team says. Knowing the shear stiffness the material displays, as well as what happens when it endures friction, will enable physicists to understand it in more detail, therefore making it easier for them to use it for practical applications.

An important aspect of using any material is knowing what its mechanical limitations are. Once these are known in the case of graphene, it may be possible to use it for developing new composite materials.

Working together with colleagues at the US Office of Naval Research (ONR), the UB team used chemical vapor deposition (CVD) to grow sheets of graphene on copper foils. The process was carried out in a quartz tube furnace, at temperatures exceeding 1,030 degrees Celsius (1,886 ºF).

“To improve the design of graphene nanosensors it is important to understand the mechanical behavior and the natural intrinsic damping and internal friction of graphene,” researcher Fabrizio Scarpa says.

“Our findings indicate that graphene produced using chemical vapor deposition could be a vital alternative for nanomechanical sensor applications,” the expert goes on to explain.

Details of the study are published in the latest issue of the scientific journal Nano Letters, in a paper entitled “Shear Modulus of Monolayer Graphene Prepared by Chemical Vapor Deposition.”

Scarpa holds an appointment as a professor of smart materials and structures at the UB Advanced Composites Centre for Innovation and Science (ACCIS). He and his colleagues believe that graphene may be used in nanoelectromechanical resonators or nanosensors.

14 DAY TRIAL //

14 DAY TRIAL //