Just last week, Iran began to develop its own medical 3D printing technology, and 3D printing technology in general, because there are certain restrictions in place that prevent 3D printers from being imported from the USA.

Now, we see another instance of Middle Eastern and Asian countries taking matters into their own hands when it comes to additive manufacturing technologies.

Back in 2012, SoftOnix was established in Pakistan. Being a company that provides 3D printing services and 3D printers on demand, it didn't see much action until later 2013.

However, demands for 3D printers started to come in fast and often, according to CEO Tayyab Alam, and now the company has decided to release the first ever 3D printer to be made in Pakistan.

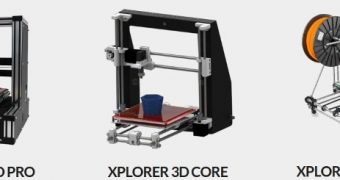

Enter the Xplorer 3D, which isn't so much a 3D printer as a brand that 3D printers will sell under. As point of fact, there are three Xplorer 3D printers up for order on the website, not just one.

The Xplorer 3D Basic has a price of 65,000 Pakistani Rupee, or PKR 65,000 for short, which is the same as $650 / €480, more or less. The Xplorer 3D Core sells for PKR 145,000 / $1,466 / €1084. Finally, the Xplorer 3D Pro is priced at PKR 195,000 / $1,950 / €1,440.

Curiously, all of them have the same build volume of 200 x 200 x 200 mm / 7.87 x 7.87 x 7.87 inches and a resolution of 100 microns per layer (which isn't stellar but not poor either).

Admittedly, it is fairly ironic and amusing that Portabee GO, the world's first portable, foldable 3D printer has a better resolution (50 microns), but that's neither here nor there.

Nevertheless, even at 100 microns, the Xplorer 3D printers are comparable to the printers up for order in the USA, Europe and Japan.

That said, SoftOnix intends to add an Xplorer 3D PRO-XL to its lineup soon, but did not give an exact date or a price for it. The build volume will be of 3870 cubic inches / 63,417 cubic cm. It will allow for even prototyping of large mechanical parts, or making the final products themselves if needed, assuming those parts are made of plastic.

As you may have surmised, the Xplorer 3D printers all use FDM 3D printing technology, or Fused Deposition Modeling, whereby an extruder uses a superheated nozzle to melt plastic and use it to “build” items drop by drop.

14 DAY TRIAL //

14 DAY TRIAL //