It might sound odd considering how many sci-fi works use scanners to detect all sorts of explosives and foreign elements, but the methods used by man to really find bombs and mines are a lot more, shall we say, primitive.

As you might have guessed, that's our way to ease you into the truth that dogs are still being used extensively to locate buried explosives.

Dogs can detect scents from very great distances, and they can do it very quickly thanks to how their olfactory sense works.

Basically, they exhale and then quickly inhale to pull back fresh odors, up to five times per second. Having 50 times more olfactory receptors than humans helps, as does having much of the brain dedicated solely to processing information received through the nose.

Since gene therapy or other means of enabling man to match animals in this area is still out of the question, machines are, once again, our saving grace.

The answer is 3D printed dog nose models

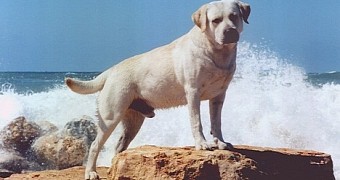

Researchers from the US National Institute of Standards and Technology have begun to 3D print anatomically accurate models of dog noses. Specifically, models of the nose of female Labrador Retrievers.

They hope to use it to finally develop that elusive bomb detection technology that pretty much every futuristic novel or TV series has. Or at least a real world equivalent.

They want to duplicate the scent sensitivity and also see how the shape of the dog's nose affects that ability to detect even the slightest nuances in smell.

The process goes like this: a CAD model (which the team created based on scans of the dog nose) was 3D printed with a Stratasys Connex 500 3D printer.

They were even able to selectively print different substances into the object, allowing the designers to distinguish between the harder and softer parts of the dog nose replica.

The research team intends to use the research data to develop vapor sampling machines, security systems (for airports and other public venues), etc.

The costs of the project

More like the costs of the printer really. The Connex 500 demanded a payment of $228,977 / €180,345 from the organization. A huge price compared to consumer printers selling for less than a grand. It's a good thing additive manufacturing can be used for pretty much anything because otherwise the expense wouldn't have been approved for a project like this.

14 DAY TRIAL //

14 DAY TRIAL //