Light fixtures probably weren't the first thing that came to people's minds when 3D printing technology really started to make itself known to the world, but it turns out that they are popular projects indeed.

Granted, lampshades were easy enough to swallow, especially the kind that imitated the shapes of certain animals which children may find reassuring at night, like that elephant nightlight that a dad 3D printed for his daughter not long ago.

Other projects were more practical and futuristic in nature. There is no better example we can give than this self-assembling lamp. Technology really has advanced a great deal.

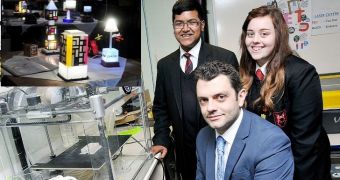

Now, lamps have once again stood out at a public event, specifically the annual Arts, Products and Textiles exhibition held by Ladybridge High School in Bolton, UK.

There, Phil Cotton helped several students to design, develop and put together prototypes of functional lamps created by means of 3D printing technology.

The lamps were very well received by the people who visited the exhibit and earned the students high grades from Phil Cotton himself, who is the school’s head of product design. All this is very good news, since the students were in their final year and could use the extra credit.

The students were actually quite lucky to collaborate with the man, since Phil Cotton won the 3D Printshow 2013’s Educational Excellence Award. He was the first teacher to even be nominated for a major industry award for education.

Several student designs earned some of the highest marks Cotton ever gave in his career as a teacher, and to show how good they were, the projects were presented at the exhibition to allow parents to see for themselves exactly what kind of work their offspring have been performing.

It is unclear to what extent the lamps are 3D printed though. The lampshades are a no-brainer, and maybe the main bodies as well, but the circuits inside were probably assembled by hand from normal parts. It's not like a regular, plastic 3D printer could ever print circuits, let alone assemble a complex electronic device mid-print.

Admittedly, there are printers, or concepts of printers, that can put together electronic boards and the like, but they weren't among the resources that Cotton's students had access to.

On the flip side, this does raise the question of how much time is still left before such things do become resources available to everyone, or at least to every student interested in 3D art and electrical engineering. Probably not as many years as one would be tempted to think.

14 DAY TRIAL //

14 DAY TRIAL //