When it comes to using 3D printing technology in the raising of buildings, most methods have focused on ways to print foundations and walls directly out of concrete. A new group of researchers, however, from Cornell University and Jenny Sabin Studio, have revealed a new way.

Essentially, instead of using a huge printer or the Minibuilder robots to raise a structure from the ground up, they have created 3D printed interlocking bricks.

They believe that this method, based on sophisticated geometry, could be more useful in large-scale constructions. And they do have a point, since it's not exactly possible to create a 3D printer big enough to, say, build a skyscraper.

The minibuilders we have mentioned might be able to pull it off, if they use a material strong enough to withstand its own weight, but even they can't solve the matter of steel beams. You can only build concrete up so high before it collapses under its own weight.

The group that came up with the Polybricks is composed, among others, of Jenny Sabin, Martin Miller, Nicholas Cassab, and Andrew Lucia, of Sabin Design Lab, Cornell University and Jenny Sabin Studio.

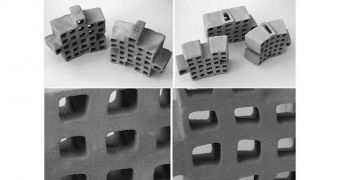

The polybricks are made of ceramic and look like cinder blocks, but fit together with others of their kind perfectly, without any need for mortar but just as safe.

The designers have studied wood joinery techniques and have developed a new tapered dovetail where the direction and severity of the tapering depends on the local geometric orientation of each component.

Long story short, the force of gravity locks adjacent components together because the slope of the surface is generated in such a way that the narrow end of the tapering is always near the lower face of the surface.

A ZCorp 510 powder-based 3D printer was used to print the bricks, and there is almost no waste associated with the process at all. The labor needed for a construction will be reduced as well if the Polybricks are used instead of regular bricks and mortar.

Convenience is also a factor, since the Polybricks basically let you build a house, or whatever else, from a single material. And one of the best parts is that the Polybricks are hollow, making them very light and, due to the less material used, more cost-effective.

We haven't heard of any construction firms or architects that have adopted the polybricks yet, but that is only because the breakthrough has just been published.

14 DAY TRIAL //

14 DAY TRIAL //