Most consumer 3D printing technology revolves around objects that we can see and touch with the naked eye, but research bodies have been dedicating much of their time and resources to the study and perfection of microscopic objects.

The 3D printed cushioning material recently invented by a team of scientists and engineers from Lawrence Livermore National Laboratory (LLNL) is a sort of bridge between the two.

A new type of cushioning material, it will definitely be touched a lot by people, both with and without meaning too, like when they fall or bump into something padded with it.

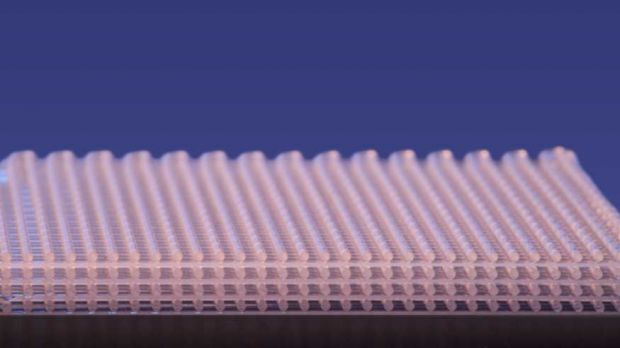

However, the additive manufacturing technology that enabled its creation uses direct ink writing at a microscale level.

The method created a material much like rubber, a material with complex architectures called cellular elastomers, architectures that can be controlled.

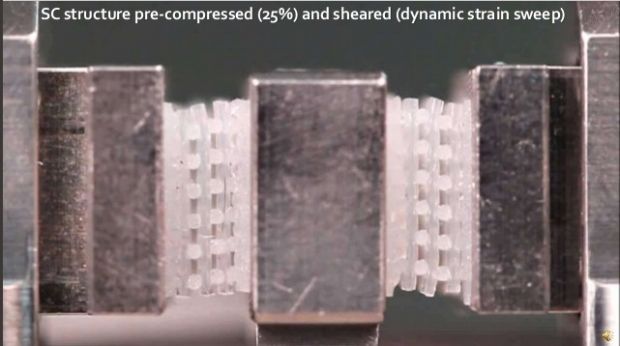

That's right, this material has programmable properties. So far, two types of 3D printed cushioning material have been created.

One has a stacked inline configuration is stiff but bucks under pressure. The other, with staggered configuration, is softer and bends when more pressure is placed on it. In both, the material is exactly the same.

LLNL has patented the technology and intends to further increase the variety of properties while marketing the new “mattress.”

14 DAY TRIAL //

14 DAY TRIAL //